展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

製品の説明 :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

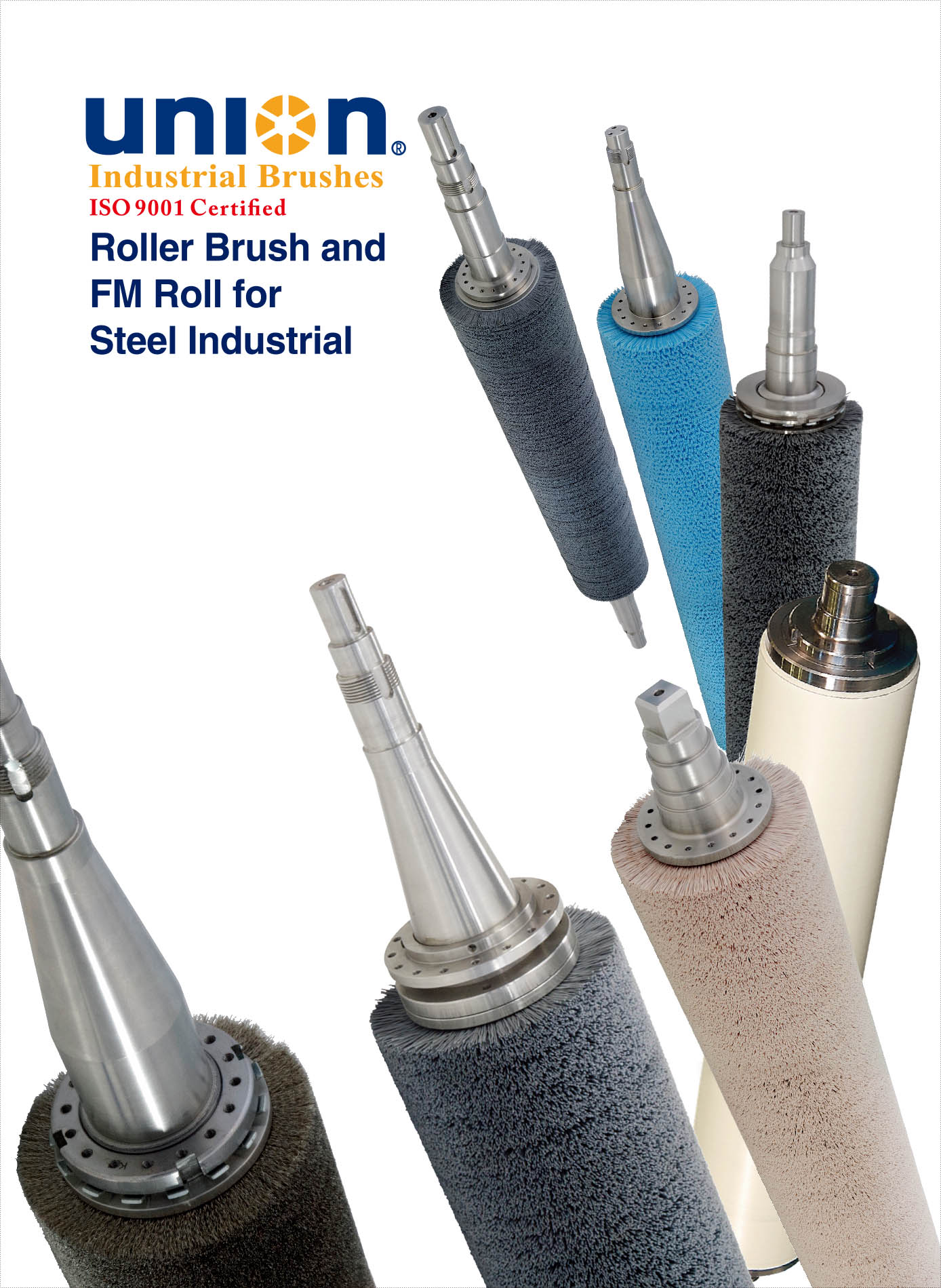

EANG LIAN CORPORATION

製品の説明 :

Steel industry, metal plates rolling production line, wire drawing production line and in processes such as acid pickling, degreasing and cleaning after annealing. Surface treatment such as brushing, grime removal, cleaning, etc. as part of large-scale equipment manufacturing processes for various types of automated production lines.

HUI-JING ELECTRONIC CO., LTD.

製品の説明 :

★ Multiple output type for many CNC controllers

★Multiple output types compatible with different CNC

control systems

★Optional enable micor switches for application

★Meet customers’various demands

★Optional Emergency Stop switch

★Magnetic back cover

★Dust & Water proof (IP65)

★Optimal solution

★Provide reverse polarity protection

★Easy to handle

CHIAH CHYUN MACHINERY CO., LTD.

製品の説明 :

The CT1-76YM is designed with a combination of double spindle and single turret.

■ ∅76mm enlarged spindle bore is ideal for turning large workpieces. ■ 16-positions power turret with Y-axis, it can complete machining on parts in the main or sub spindle. In addition, tools can be placed facing either the main or sub spindle.

G-TECH INSTRUMENTS INC.

製品の説明 :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

RUN ACE CO., LTD.

製品の説明 :

Gambini Meccanica in Italy specializes in the production of high-precision transmission gear rows, gears and screws. The main application areas of the products are industrial automation, aviation, grinding plants, steel plants,

Wood, stone, aluminum processing machines, textile industry machines, material handling equipment, trucks and hydraulic cranes, petrochemical plants, food processing machinery and agricultural machinery.

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

1. Automatic separating the parts and blasting abrasive, reduce the blasting time.

2. Equipped with air flushing dust collector, which automatically separate the dust. Correspond with the environment protection test and avoiding pollution problem.

3. Diagonal type blasting method. The operator can work and check the parts directly, which can avoid the parts missing.

4. Simulating the blasting angel and intersect blasting by CAE computer in order to achieve the surface blasting action more efficiently.

5. Suitable for bicycle and auto mobile parts, blasting efficiency increase and reduce the producing cost.

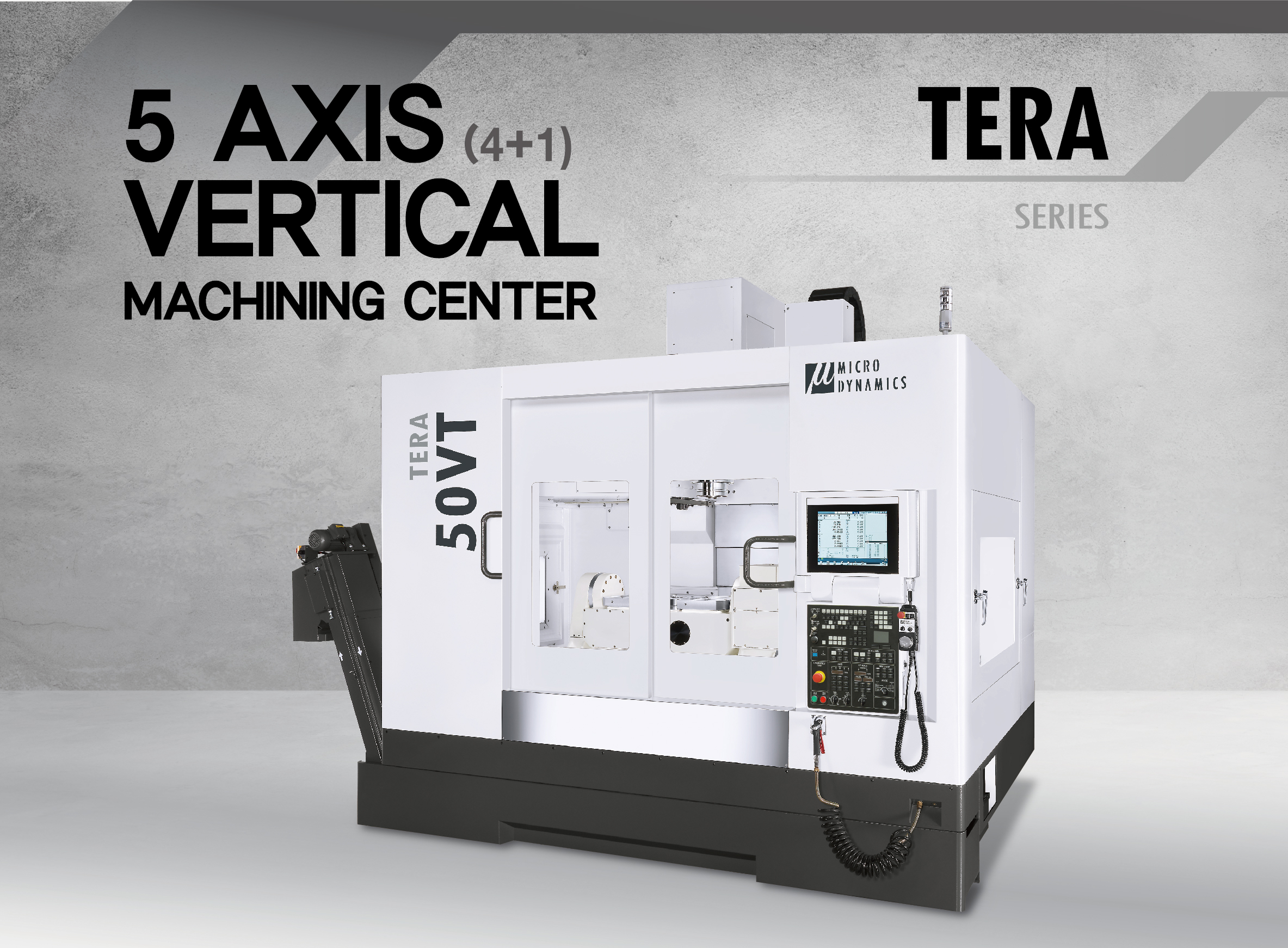

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.