展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

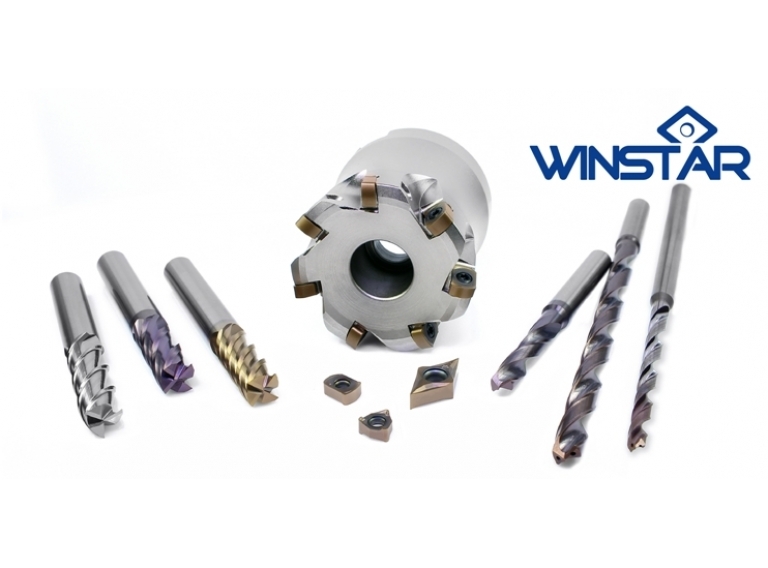

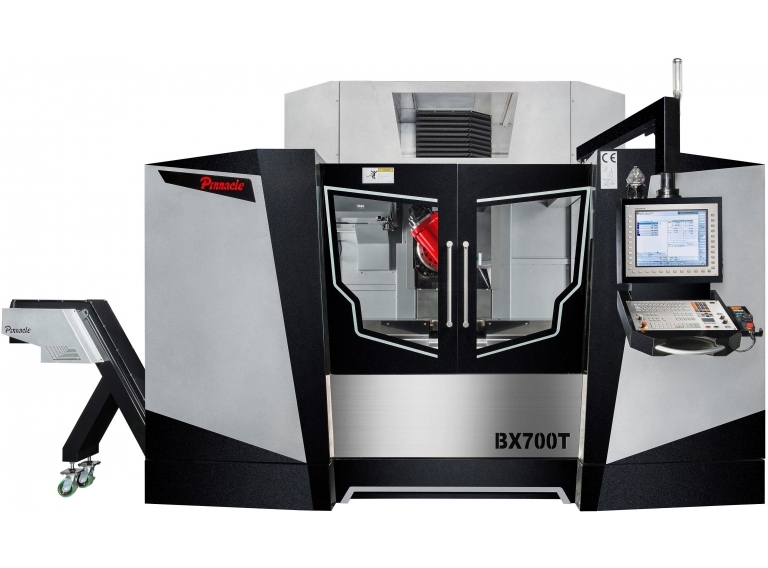

NUMEN MACHINERY CO., LTD.

製品の説明 :

Delta 6 is designed for new dimensions in precision, contour accuracy, surface quality and productivity. Maximum dynamics, precision performance milling and HSC machining are accurately executed. Offering wide range of applications including electronic watch, optical, medical and die mold.

Cartell Chemical Co., Ltd.

製品の説明 :

◆甲基瞬間膠:可應用於不同材質與間隙之黏接。特別是針對塑膠,橡膠、金屬彼此之間的接著。

◆乙基瞬間膠:對於乾燥、多孔性、低表面能材質或酸性表面等困難接著材料,或低濕度環境中,均可達到快速及有效接著的效果。

◆乙基瞬間膠 (抗震動/耐衝擊/強韌彈性):此系列產品是使用橡膠或酸酐增韌劑配方,用於吸收和分散施加在接著劑膠層上的衝擊和應力,從而形成更堅韌的接著,有助於提高固化後瞬間膠的剝離強度和抗衝擊性。

◆低氣味&低白化瞬間膠:極低氣味極低白霧,不影響接著劑的固化時間、接著強度或物理性能。

◆光固化瞬間膠:具有瞬間膠和光固化接著劑的所有優點,沒有任何侷限性。

◆醫療器材接著劑:通過 ISO10993-5標準的嚴格認證,確保了無論是手術工具、診斷設備還是其他醫療器材的生產過程中的高度生物相容性與安全性。

◆特殊應用瞬間膠:針對高溫、高濕等不良環境下之接著需求所研發產品。

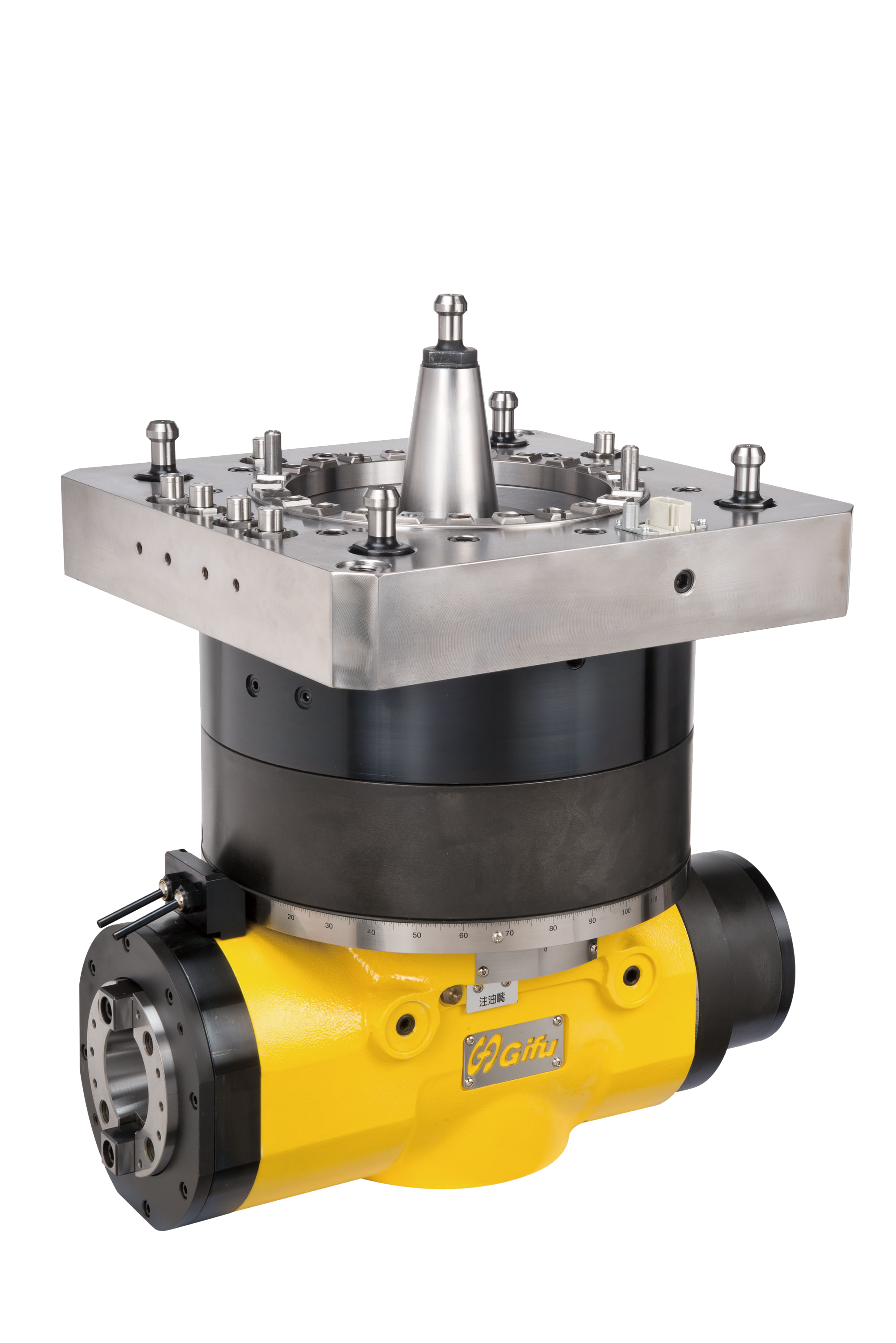

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Model:Semi-Auto 90-degree CTS Milling Head (Maximum Torque:1000N.m) (Maximum RPM:2000r.p.m)

1.The exquisite design helps to reach the purpose at the most limited space.

2.Adopts spiral bevel gear with high rigidity and accuracy to keep reliable running and long life time of the product.

3.High torque transmission and high cutting efficiency.

4. The hydraulic tool pulling design of the spindle makes easy tool loading.

5.The design of extension body is exquisite with solid structure.

6.High accuracy, low vibration and good dynamic rotation accuracy.

7.It can be adopted for CTS system.

HAI JU TRADING CO., LTD.

製品の説明 :

螺紋護套, 是一種高強度的緊固件, 能在低強度的材料中提供高強度的緊固功能,螺紋護套已經在市場上發行約超過60年, 這些不銹鋼螺紋護套是以菱形輪廓的鋼線製成彈性螺旋, 並且經過質量驗證。護套安裝後,在導舌預定斷裂點折斷導舌,以使螺紋護套通孔.<br />

<br />

<br />

<br />

由於不斷的改良與優化,HELICOIL®Plus 螺紋護套 現在更容易安裝。<br />

<br />

與HELICOIL®經典螺紋護套做比較, HELICOIL®Plus的線圈有特殊的起始, HELICOIL®Plus同樣是以菱形輪廓的鋼線製成的彈性螺旋, 於由線圈有特殊的起始, 安裝時可以像螺絲一樣被定位並擰入, 搭配現有的同一公稱系列工具組裝,與HELICOIL®經典螺紋護套的安裝做比較, 能縮短將近20%的安裝時間. <br />

<br />

<br />

<br />

HELICOIL®Plus 提供高強力, 能從側面到側面, 將力傳遞到螺紋。<br />

<br />

這種高度可靠性的系統已被德國和國際工業產權提交。 HELICOIL®Plus根據一致性的材料和質量規範生產螺紋護套, 並滿足國家標準化以及航空和軍用標準的要求。 除此之外, 許多領先的大型用戶亦以HELICOIL®螺紋護套為基礎做為製造標準。<br />

<br />

<br />

<br />

<br />

<br />

Rm = tensile strength 1,400 N/mm2 min.<br />

HV = vickers hardness 425 HV 0.2 min.<br />

RZ = roughness depth approx. 2.5 μm<br />

μG = reduced thread friction, results in increased preload-force FV<br />

τt = reduction in torsion stress in the screw shank<br />

===========================================================<br />

<br />

HELICOIL®無尾螺紋護套<br />

<br />

1.無折斷,無斷裂<br />

-無風險的留在組件<br />

-減少安裝時間<br />

-減少測試時間<br />

<br />

2.降低刀具磨損<br />

-工具刀片的磨損最小<br />

-易於維護<br />

<br />

3.提高品質<br />

-簡單化的品量保證<br />

-高強度的配合螺紋盲孔深度或預裝配組件<br />

-符合NA0276標準

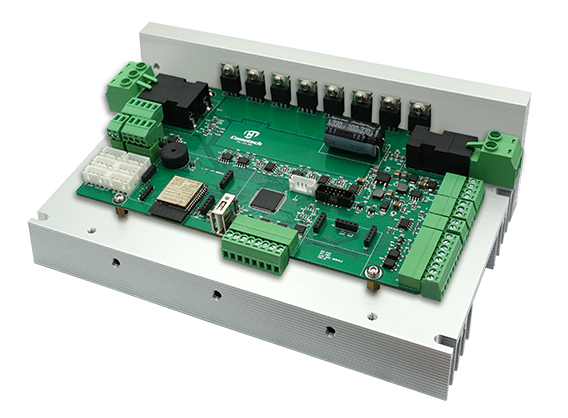

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 800W

-Rated Current: 35A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Speed Control: Analog input, Digit input, PWM, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications