展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

MANFORD MACHINERY CO., LTD.

製品の説明 :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

■ The unique IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

■ Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

■ High precision rotary encoders in the B and C

axes as a standard feature, allowing for the most demanding machining accuracies.

■ ø650 mm table provides stable machining performance with a wide machining area and trunnion support.

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

1. T structure bed with high-quality cast-iron frame for enhanced rigidity and stability.

2. Extremely rigid mobile column with linear guide ways ensures stability and cutting accuracy while allowing rapid traverse of the X, Y and Z axes.

3. High rigidity roller type linear guideways, rugged massive linear guideways on X, Y and Z axes maintain precision and ensure a rapid traverse rate.

FAIR FRIEND ENTERPRISE CO., LTD.

製品の説明 :

★Gantry type structure

- Designed with a gantry type structure, the Feeler U800-5AX 5-axis machining center has the feature of spacious machining space, allowing large workpiece to be loaded and unloaded with ease. It is also convenient for operator to check the current machining condition at any time.

★U-shaped construction of base and column

-The advanced U-Shape structure significantly increases structural rigidity and machining accuracy.

-X.Y.Z axis rapid traverse rate reach 48m/min.

- Suitable for equipping with a large diameter of rotary table.

★Three axes overlap and separated from two rotary axes

- This design avoids a distance between the machining point and the intersection point of two rotating axes.

- Easy to compensate for the errors of radius on rotating axes and movement on three linear axes to ensure the machine's stability and accuracy.

★Separated design for three axes moving area and machining area

- This design feature not only makes chip removal more convenient, but also enables better chip-prevention capability of the machine.

- The rotaary shaft speed is increased by 800 rpm, which makes the turntable have a high-speed turning function.

EUMACH CO., LTD.

製品の説明 :

HSM-5X系列是最新的機器與萬能的應用,完美回應數控五軸加工與工件的定位與刀具軸空間要求,為複雜零件的加工提供了廣闊的應用範圍。

本機採用C型架構,機床為高剛性完全支撐結構,機械經久使用,能長時間維持穩定狀態,旋轉銑頭B軸與旋轉工作臺C軸為獨立分開無重迭之兩旋轉軸,便利於工件、刀具及夾制具等設計及擺放,尤其相互干涉現象較旋轉兩軸重迭之銑頭或工作臺大幅減少。並可選用車銑主軸及高速旋轉工作台,達到車銑複合綜合加工。

HSM-5XC是大型高效切割和加工應用的最佳解決方案,無論您的重點是靈活的單元生產還是大批量精密製造,如航空工業的渦輪葉輪,葉盤等,或醫療的心臟瓣膜,人工關節或牙齒等,當然,一般加工,如模具加工或僅5面或多面加工都非常容易!

本機採用實的米漢娜鑄鐵結構,三軸為重型滾柱直線導軌進給系統,能很短時間內加速到48m/min,三軸行程1020/610/610mm,力矩電機驅動B軸連續擺動銑頭0.001角度分割,旋轉範圍-30~120゚,裝進口電機主軸26&32Kw / 124&154Nm / 18000RPM/HSK-A63設計及標準長工作台崁入φ610mm由力矩電機驅動的旋轉工作臺(C軸),最大轉速50RPM承重500KG,搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,刀臂式60把刀,該加工中心用於多面高性能加工和最智能的加工概念提高了生產力。

QUASER MACHINE TOOLS, INC.

製品の説明 :

The MV1 series machines have a legendary history of high quality and proven performance, the New MV184 series has an even greater degree of reliability and performance. The design concepts of the new MV184 series combine advanced technology, performance and value for various machining applications.

Quaser produces this machine layout with the state-of-the-art digital design. Taking into consideration easy repair to reduce downtime. The MV184 series is the choice to increase part production.

NUMEN MACHINERY CO., LTD.

製品の説明 :

*High-rigidity structure design, using C3 precision ball

screw for axial feed and direct drive with servo motor.

* X/Y/Z axes installed with roller type of linear slide way

to ensure rigidity of axial movement and fast feed rate.

* Direct drive spindle.

* Suitable for various processing industries.

* 4th axis / 5th axis applications.

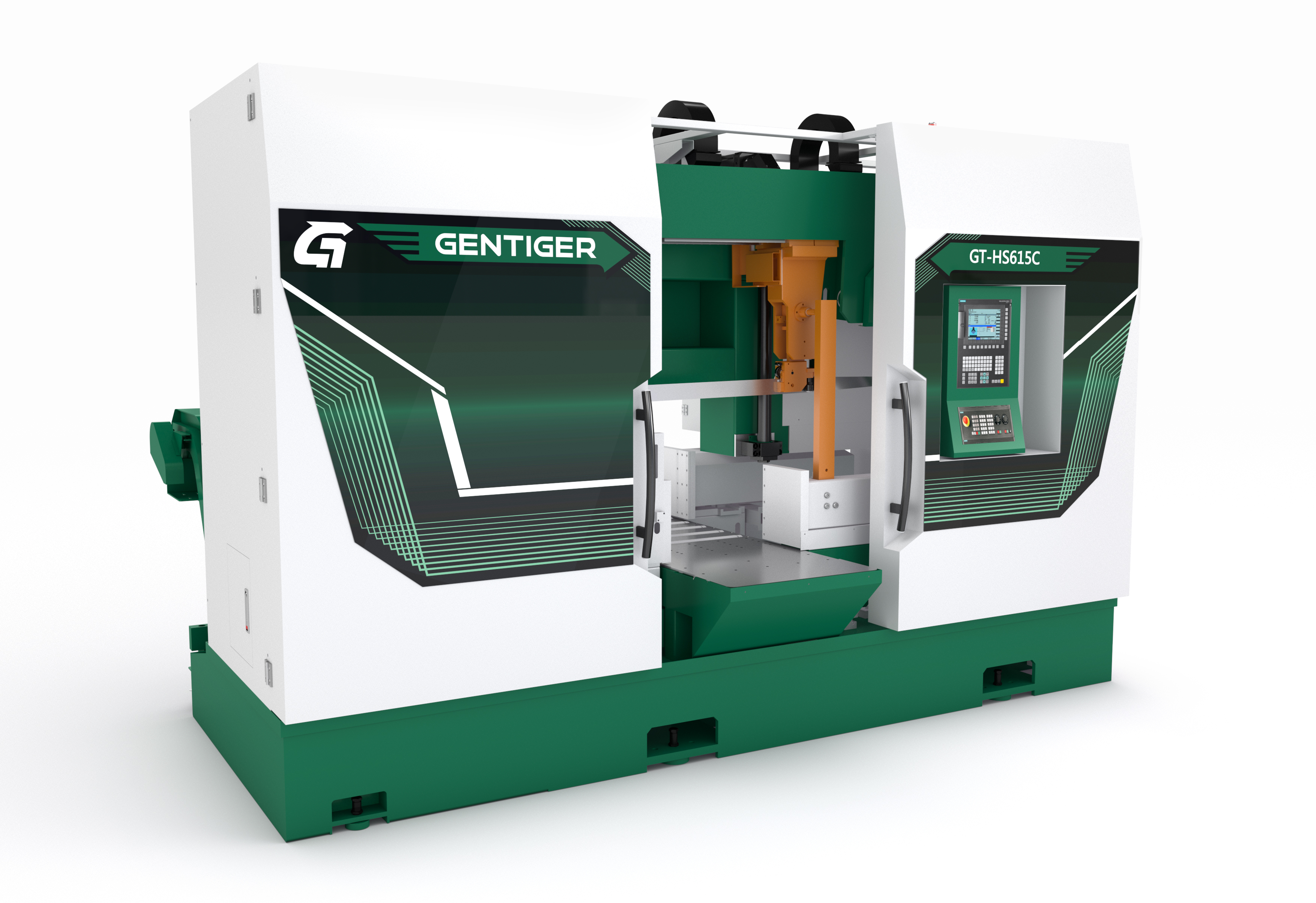

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

■ Open-type + Single Platform, suitable for general cutting applications.

■ Processing Sizes: 30001500mm / 40002000mm / 6000*2000mm (optional)

■ Laser Power: 1500W / 2000W / 3000W / 6000W

■ Laser Brand: IPG Laser (standard) / nLight / Raycus

■ Applicable Materials: Aluminum, Stainless Steel, Galvanized Sheet, Carbon Steel, Silicon Steel, Brass, Copper, and other thin metals.

REN AN INFORMATION TECHNOLOGY CO., LTD.

製品の説明 :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.