展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

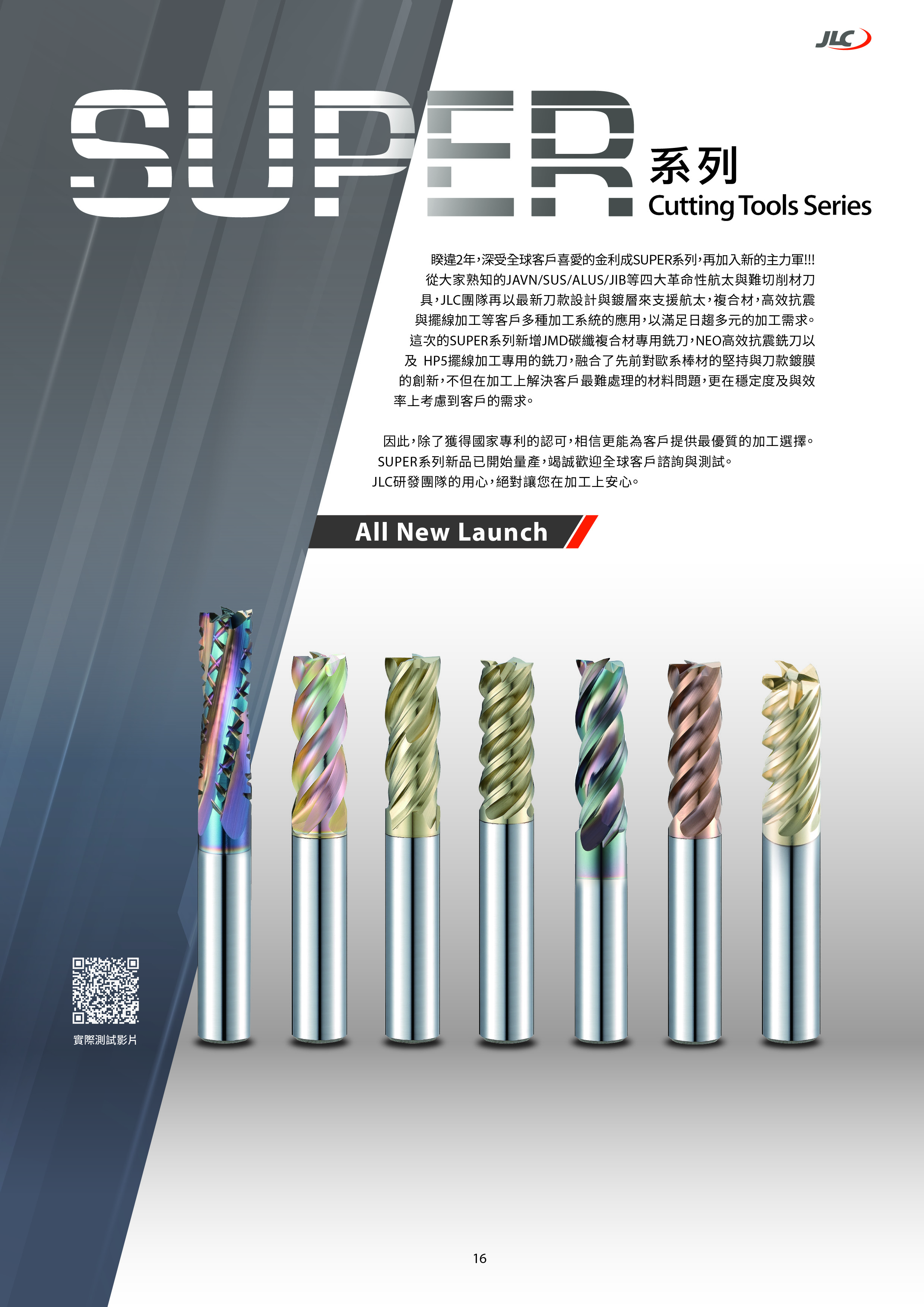

睽違2年,深受全球客戶喜愛的金利成SUPER系列,再加入新的主力軍!!!

從大家熟知的JAVN/SUS/ALUS/JIB等四大革命性航太與難切削材刀具,JLC團隊再以最新刀款設計與鍍層來支援航太,複合材,高效抗震與擺線加工等客戶多種加工系統的應用,以滿足日趨多元的加工需求。

這次的SUPER系列新增JMD碳纖複合材專用銑刀,NEO高效抗震銑刀以及 HP5擺線加工專用的銑刀,融合了先前對歐系棒材的堅持與刀款鍍膜的創新,不但在加工上解決客戶最難處理的材料問題,更在穩定度及與效率上考慮到客戶的需求。因此,除了獲得國家專利的認可,相信更能為客戶提供最優質的加工選擇。

SUPER系列新品已開始量產,竭誠歡迎全球客戶諮詢與測試。

JLC研發團隊的用心,絕對讓您在加工上安心。

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

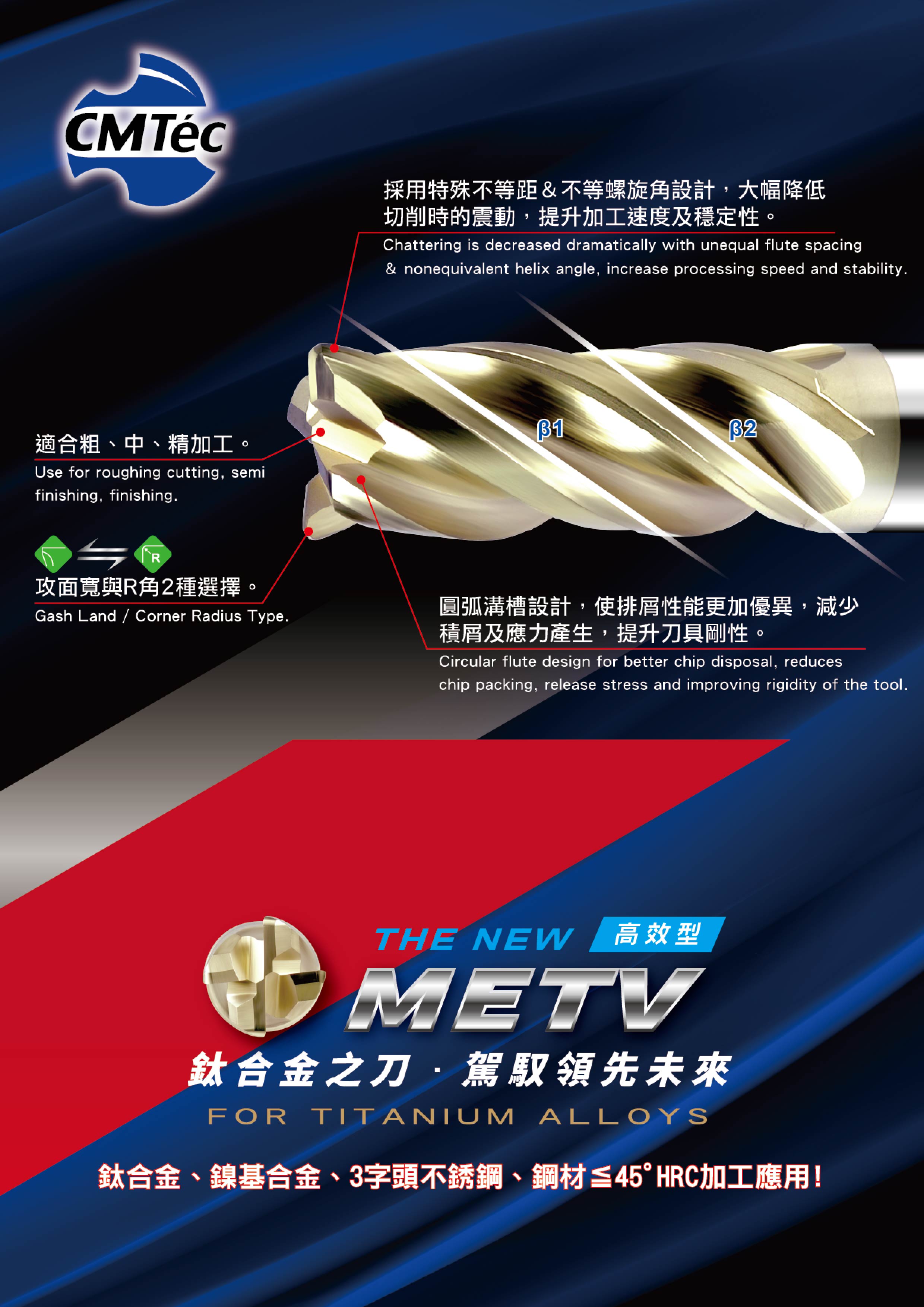

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

HON JAN CUTTING TOOLS CO., LTD.

製品の説明 :

●Internal and external threading for both left-thread and right-thread with one tooling

●Safe machining operation and easier to reach the bottom inside the blind holes

●Evacuate the chip more efficiently than the traditional milling process. shank: 20mm~40mm , Internal Thread Insert: 12I , 14I, 21I, 30I , 40I , External Thread Insert: 14E, 21E, 30E , 40E

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

NC Helix Drill cuts material by helical interpolation; serrated cutting edge minimizes chip length.

Low spindle power is not a problem, good for drilling material that generates long, soft chips.

● Reduce Your Tool Inventory

Each holder can machine di erent diameters and hole depths, saving your tool inventory and cost!

No need to peck drill or dwell in operation even machine without internal coolant.

● Lower spindle power consumption Easy to cut!

• Thanks to the small cutting load of the serrated cutting edge and helical interpolation lower power consumption. Work quicker, smarter and achieve better results.

• Circular ramping milling, maximum ramping angle is 20°. For example: tool HD27 machining Ø50 mm hole, 9 mm pitch for aluminum, 6 mm pitch for carbon steel.

● Special insert geometry - exceptional swarfs control.

• Serrated cutting edge makes the chips short and small, and easier to evacuate.

• Eliminate swarf and vibration problems while drilling di cult material or deeper holes.

● “One tool” performs multiple applications

• Not only a drill, but an end mill too.

• Small radius path to cut a hole or step hole, various curved cavity shapes on di erent materials.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

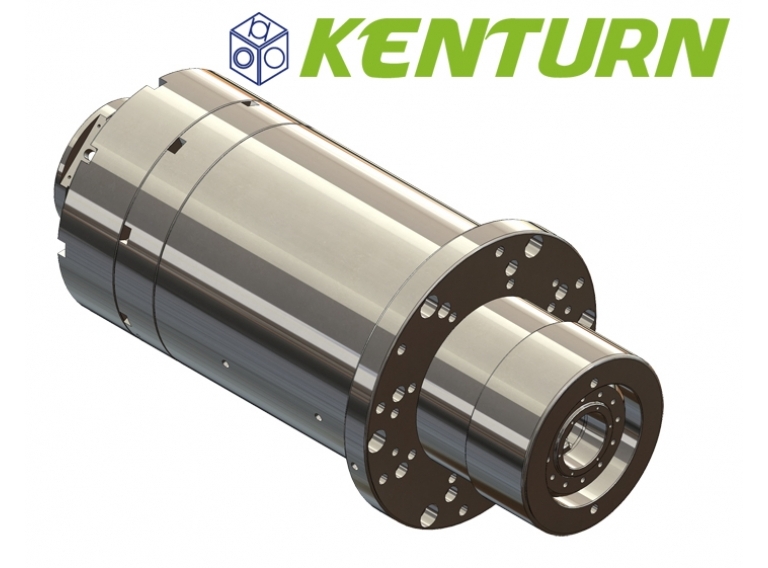

KENTURN NANO. TEC. CO., LTD.

製品の説明 :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

AE-VM features good stiffness, unequal lead and helix angle to enhance anti-vibration.

New flute design fulfills better chip removing.

New Coating “DUARISE” provides advantage on lubricity, wearability, high temperature oxidation resistance, and muti-layer structure can prevent it from thermal cracking.

Standard Type and Short Blade Type(AE-VMS、AE-VMSS):Square, Radius, and 90°(-RA) end mill.

3D, 4D Long Blade Type(AE-VML):Square, Radius, and Chip-breaking flute(AE-VML-N) end mill.

Side Milling Type(AE-VMFE): Square, and Radius end mill.