展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

These words describe the driving forces behind the design of our SMART-IV CNC surface grinding machines. They’re the standards required by the medical, automotive, mining, semiconductor, aerospace, injection mold making and job shop industries in order to meet current and future market needs and pave the way to factory automation.

This series is capable of producing complicated shapes for highly accurate workpieces along with finer finishes. The heavy-duty slide rails, one-piece base casting and hardened wheelhead guideways create a solid, rigid machine structure that minimizes vibration, movement and displacement.

Chevalier’s user-friendly grinding machines include our exclusive PC-based SMART iControl featuring conversational programming.

Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

MATRIX PRECISION CO., LTD.

製品の説明 :

ZHS-3040 combines FANUC controller and PC, it applies linear motors and direct drive motors, developing out the six-axis-control and four-axis-move high-precision grinder. ZHS-3040 can sharpen the blade of straight and helical hobs, it can also sharpen shaper cutters and Power Skiving cutters by options. Self-developed intelligent conversation window software is easy for operation. It meets the brilliant high-precision and high-efficiency performance. One machine with multi- purpose, ZHS-3040 is your best choice.

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Apply every transmission machines.

The general AC induction electric motor is designed with IEC standard. These motors fit a variety of industrial applications and it is convenient for new and used applications. Electric motor power is available from 0.25 to 20HP. The frame size is from 63 to 160.

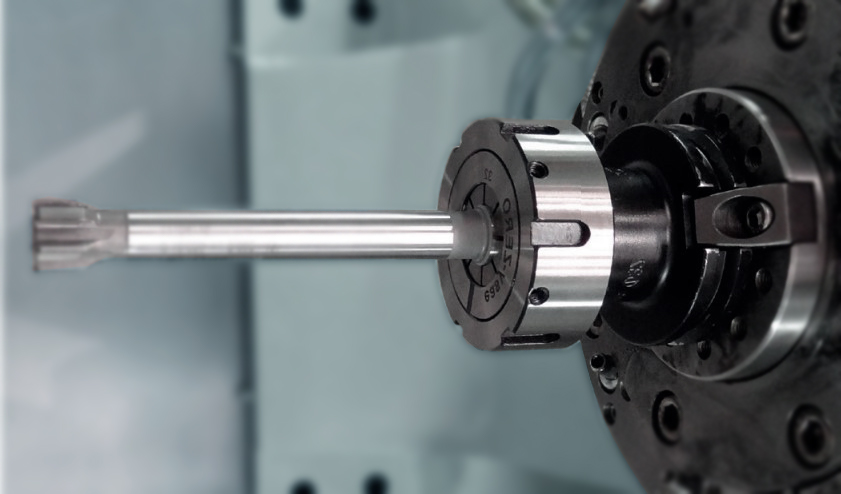

MONGTEC PRECISION INC.

製品の説明 :

Product Features

◎ Correction of runout errors and misalignment

◎ For metallic sealed and normal collets as per DIN 6499 / ISO 15488

Product Advantages

◎ Easy to set

◎ Maximum process capability due to correction of runout

◎ Extended tool life due to perfect runout

◎ Highest quality of bores due to correction of runout

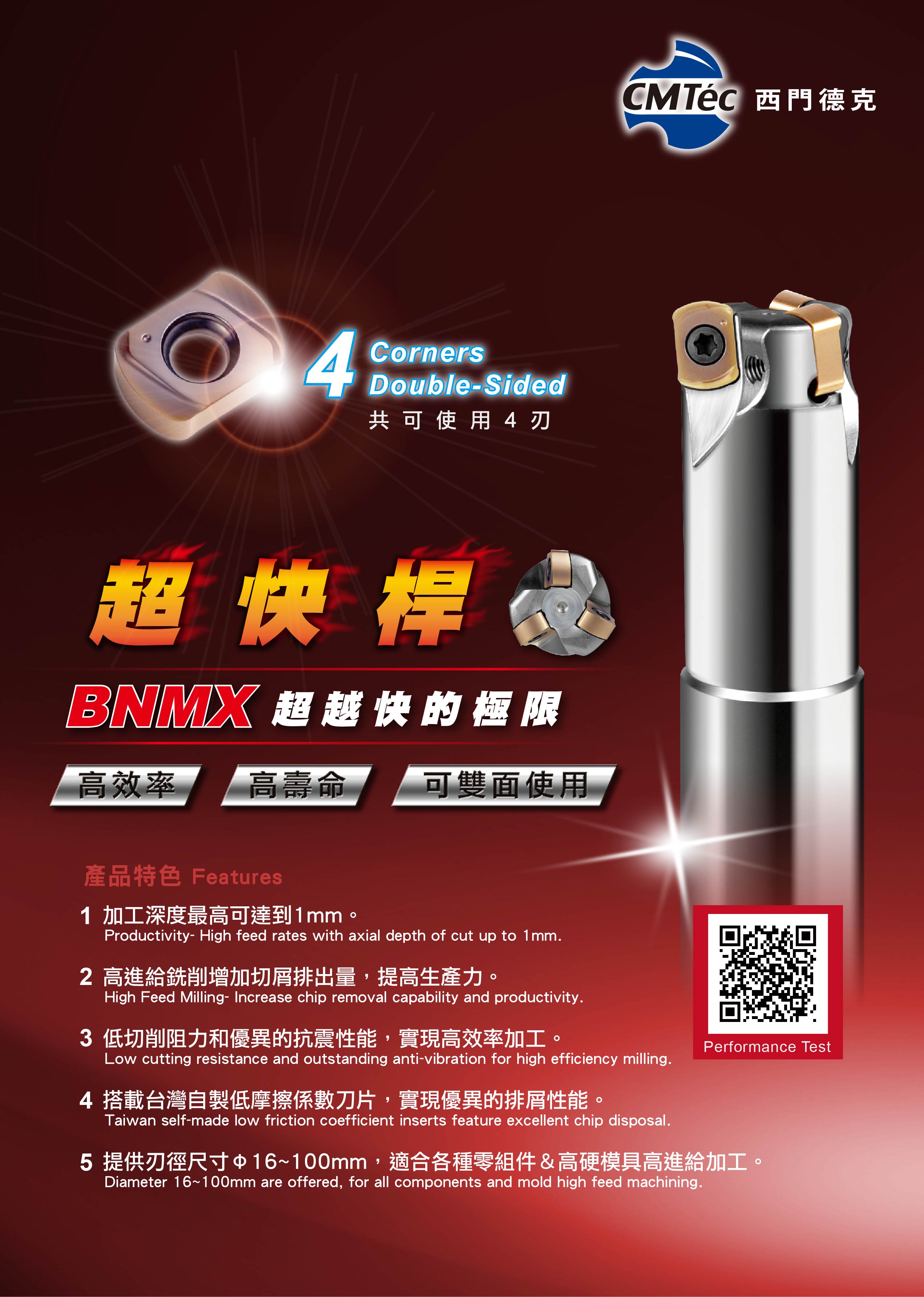

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ Productivity- High feed rates with axial depth of cut up to 1mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ Taiwan self-made low friction coefficient inserts feature excellent chip disposal.

★ Diameter 16~100mm are offered, for all components and mold high feed machining.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

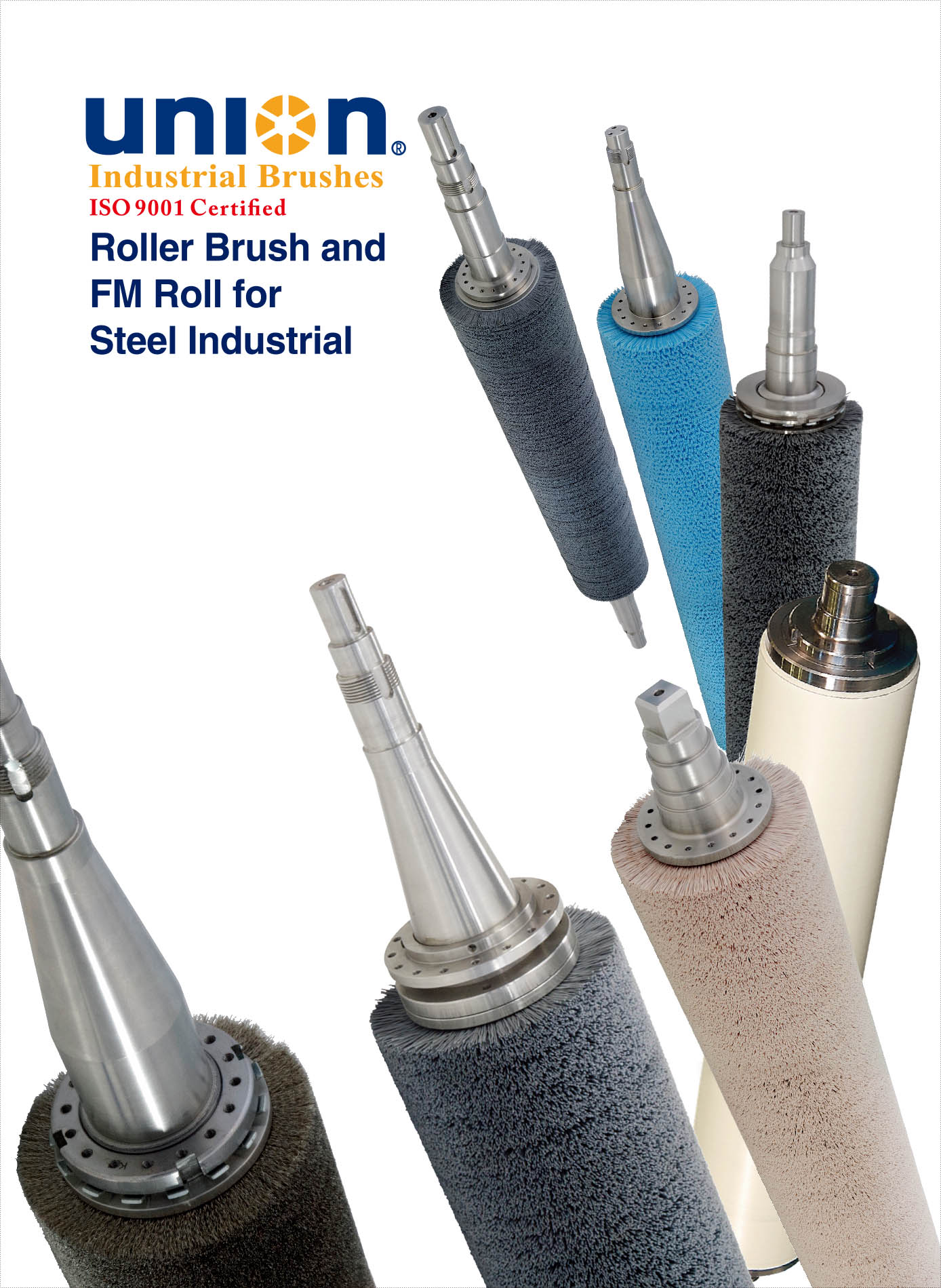

EANG LIAN CORPORATION

製品の説明 :

Steel industry, metal plates rolling production line, wire drawing production line and in processes such as acid pickling, degreasing and cleaning after annealing. Surface treatment such as brushing, grime removal, cleaning, etc. as part of large-scale equipment manufacturing processes for various types of automated production lines.