展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

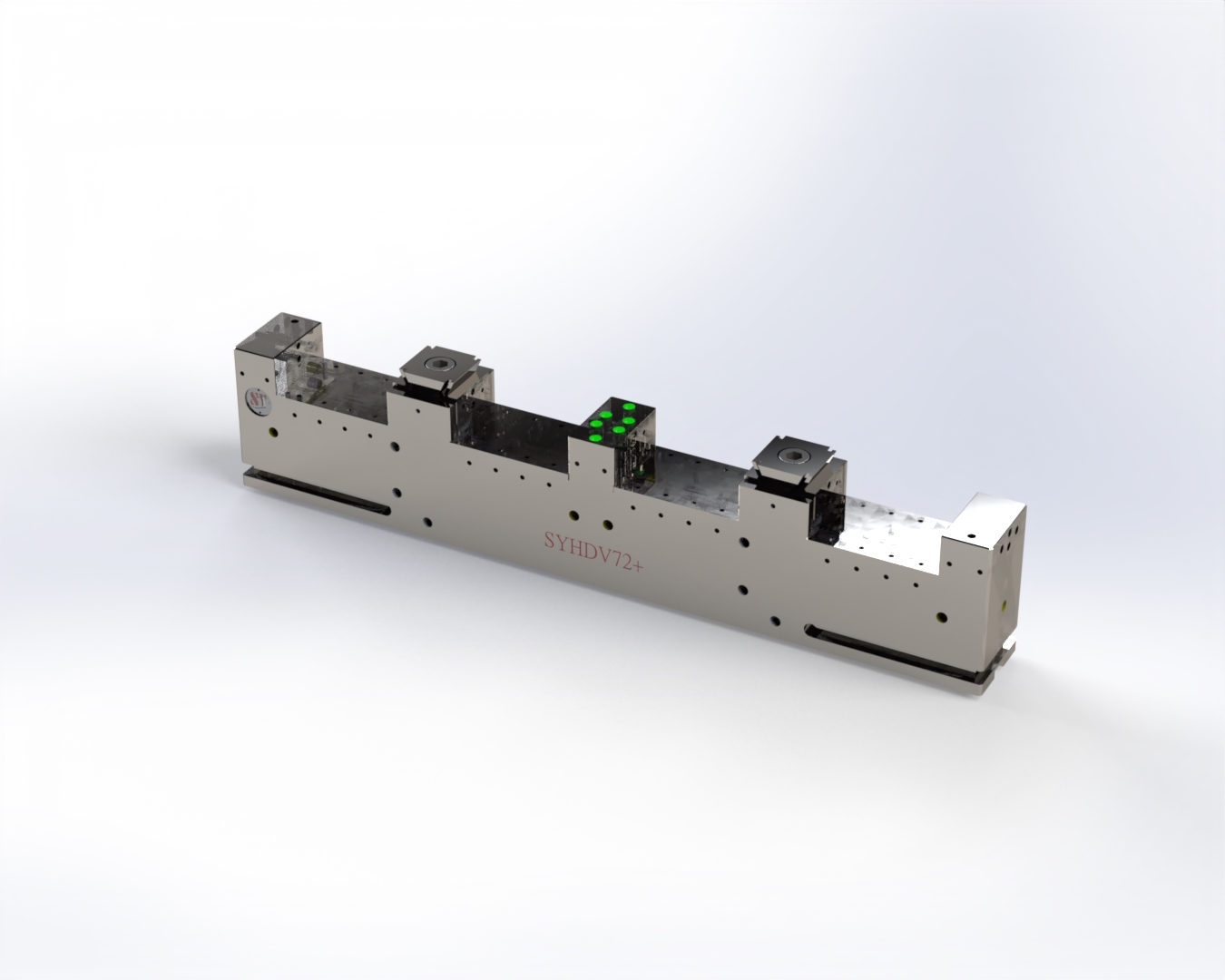

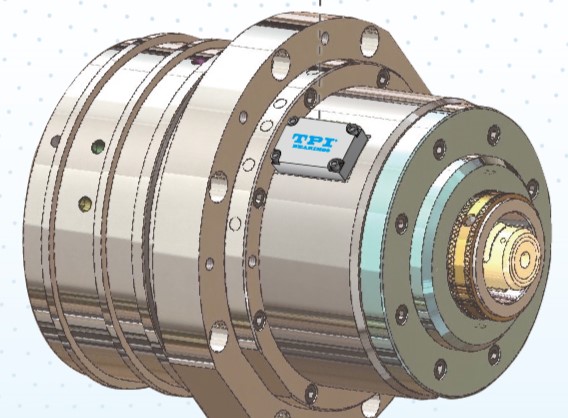

BLUM PRODUCTION METROLOGY CO., LTD.

製品の説明 :

– THOUSANDS OF MEASURING VALUES OF ALL TOOL CUTTING EDGES PER SECOND

– UP TO 60% LESS MEASURING AND CHECKING TIME

– MEASUREMENT AND MONITORING OF ALL KINDS OF TOOLS, TOOL FORMS AND CUTTING MATERIALS

– COMPENSATION OF SPINDLE DRIFT AND TOOL CUTTING EDGE RUN-OUT ERRORS

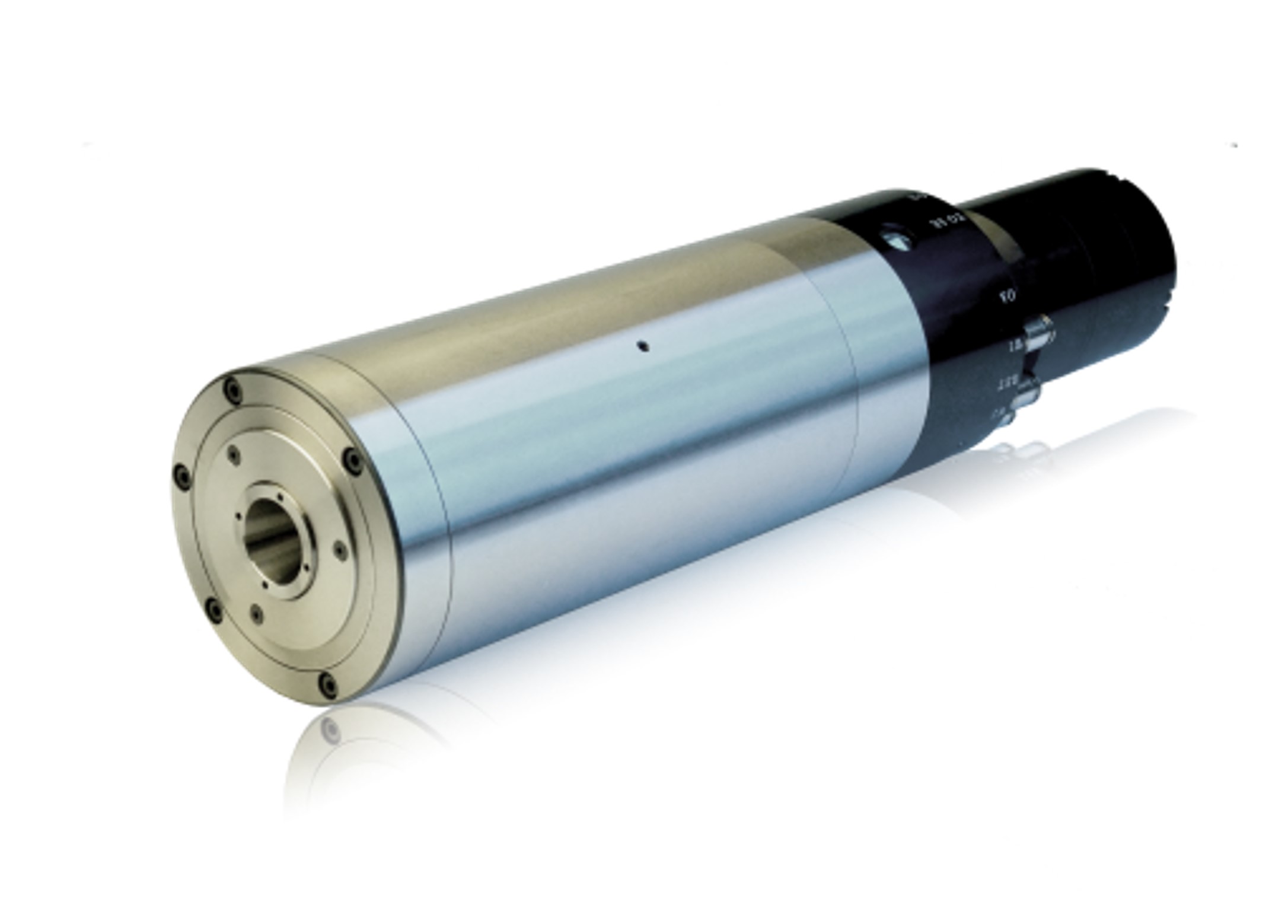

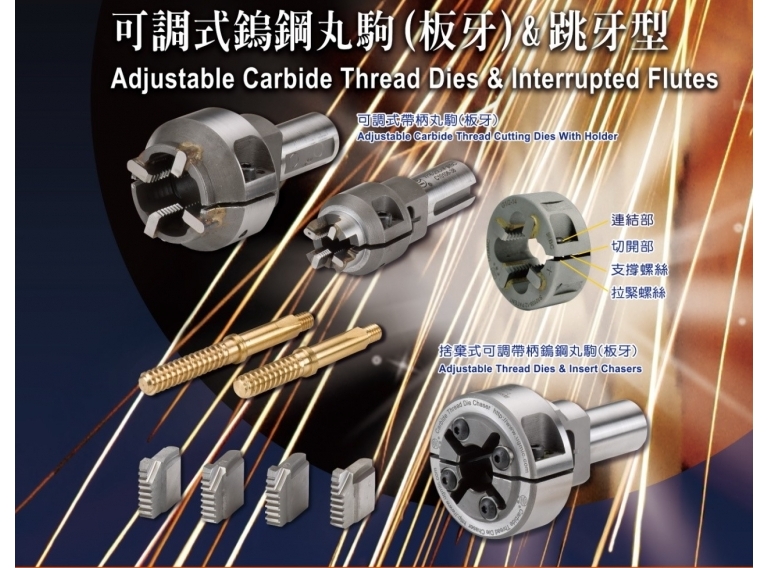

MING YANG MACHINERY CO., LTD.

製品の説明 :

The model MTY 51/65 is equipped with a dual spindle double turret and double Y axes. The machine is combined with FANUC 31i PLUS for simultaneous control on triple tool systems. The machining support two turrets for one spindle and one turret for two spindles at the same time. In other words, each process will collaborate with three tools. Mostly, the machine improves 50% efficiency.

OSCAR E.D.M. COMPANY LTD.

製品の説明 :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

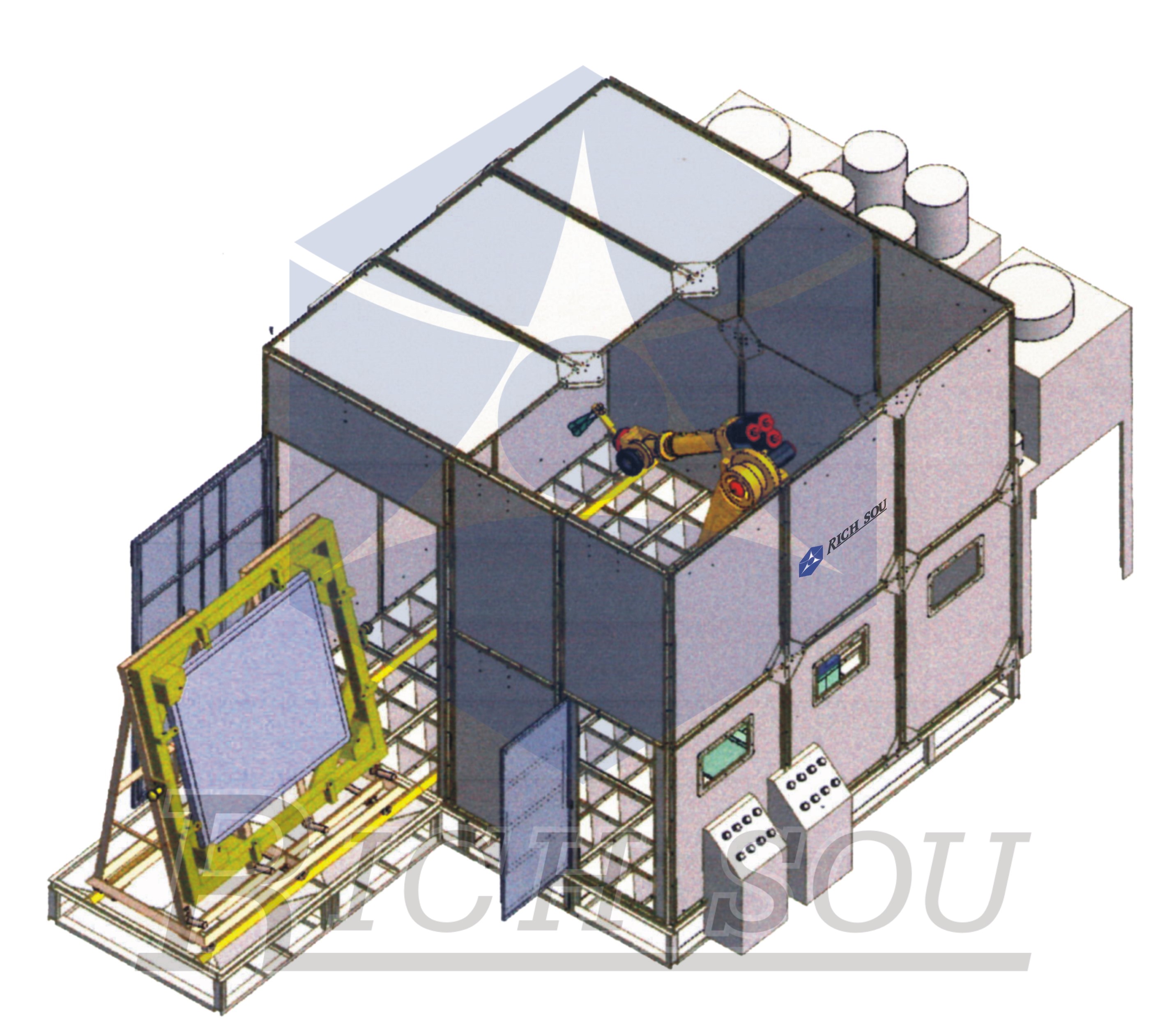

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

Rich SOU blast room provides even greater potential for improving safety and reducing operating costs when you're cleaning, finishing or surface-profiling large work pieces. With the process contained in a specially designed enclosure, blast media and debris are separated from the external environment. And the operator, equipped with safety gear, is fully protected.

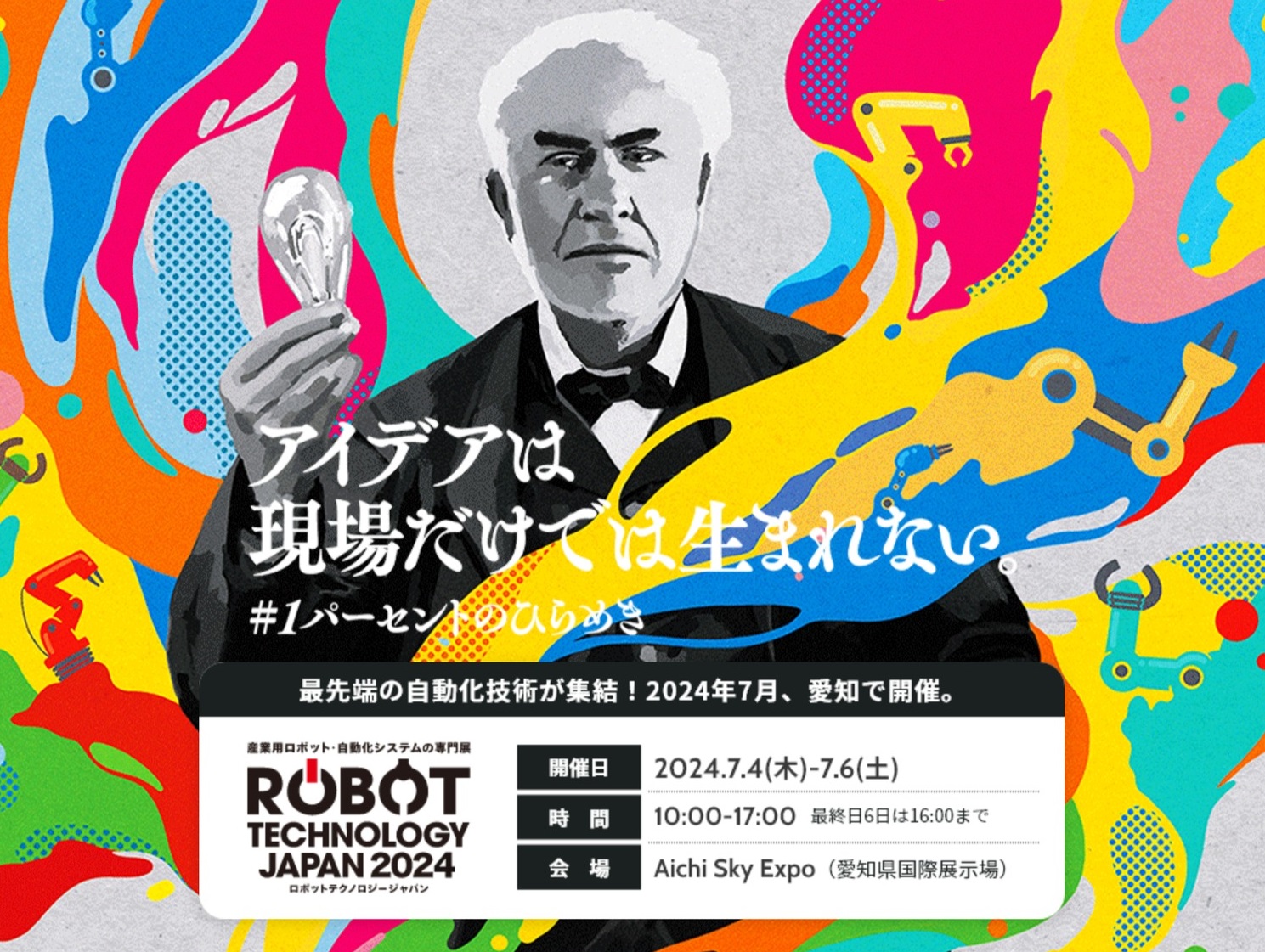

Lotus Business Information Co., Ltd.

製品の説明 :

This is one of the biggest B to B exhibitions held in “Central Japan,” an industrial area with a cluster of manufacturers. In 2022, 202 companies with 1,096 booths were registered in the exhibition.

The scope of the exhibition is specialized in “industrial robots” used in manufacturing sites and logistics bases, “devices and equipment” with industrial robots integrated in them, and “automation systems” using like AGVs/AMRs.

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.