Theme

Digital Transformation

Green Transformation

PINTAI MACHINERY CO., LTD.

Product Description :

● NC控制器配合彩色觸控螢幕,機器操控簡易<br />

● 三爪式夾持工件,夾持穩固,進給快速<br />

● 穩重的機體結構,具有最佳研磨穩定性<br />

● X,Y軸自動進給,採用伺服馬達驅動<br />

● 砂輪主軸及工件主軸均可無段變速<br />

● 砂輪主軸轉速50000 rpm<br />

● 高速砂輪主軸轉速,大幅提升加工效率,且研磨面精緻<br />

● 雙V型滑道,經熱處理硬化,滑道面經精密研磨,並貼附Turcite-B耐磨片及鏟花處理<br />

● 附三色警示燈,呈現機台操作狀態

SHENG YU PRECISION MACHINE CO., LTD.

Product Description :

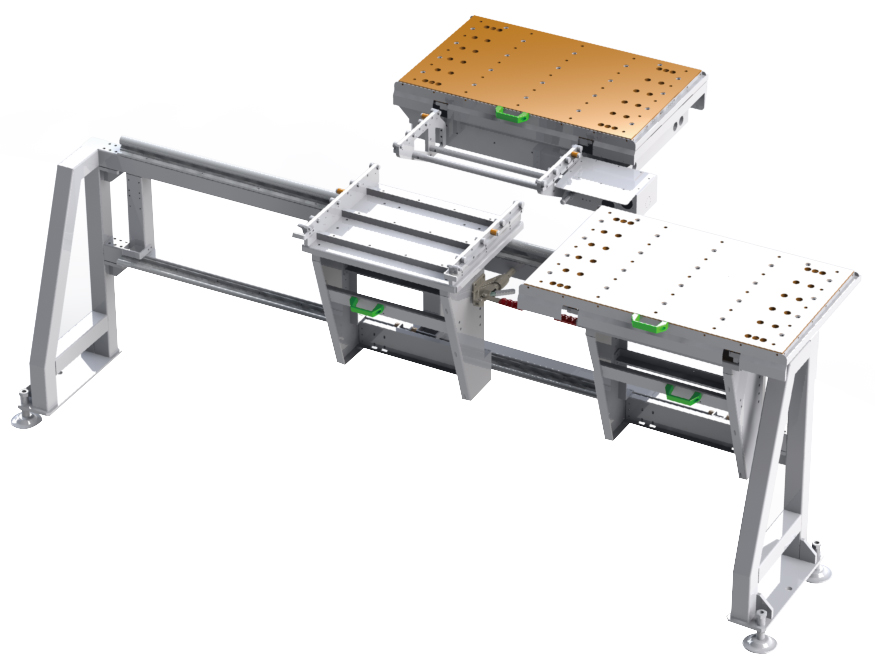

1.Applicable for various vertical machining centers and surface grinding machines.

2.Suitable for use on a new or used machine tool.

3. Reduce manual workpiece loading time.

4.Increase timely machining efficiency.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

TAIWAN FANUC CORPORATION

Product Description :

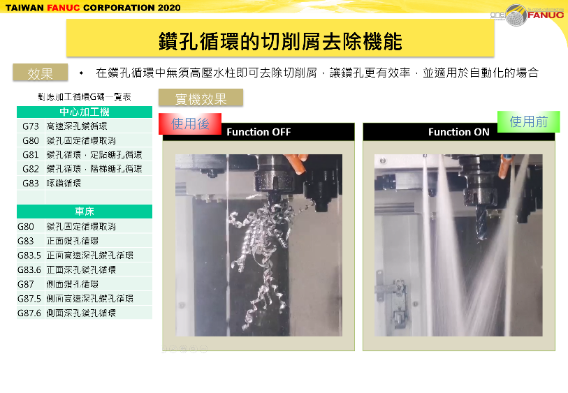

Machine center chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.

GUEY CHERNG TRADING CO., LTD.

Product Description :

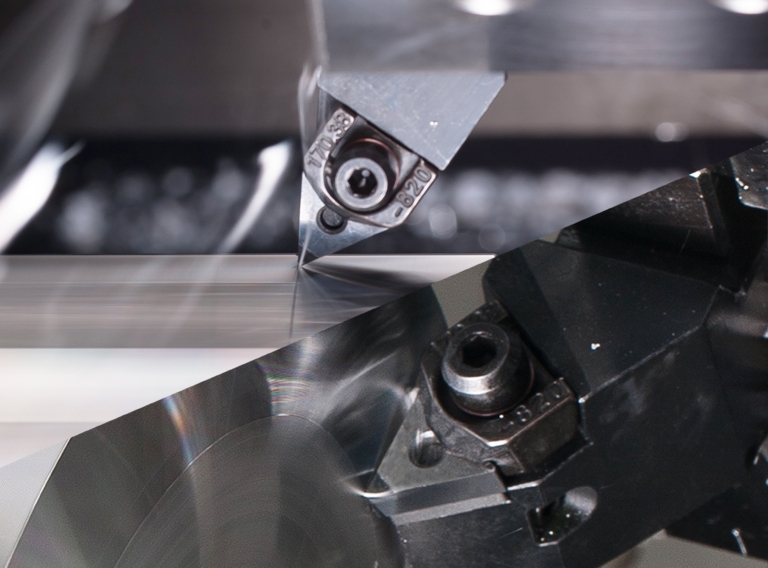

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

SAFEWAY MACHINERY INDUSTRY CORPORATION

Product Description :

1. Large through hole design.

2. Drive by dual-lead worm. Exceptional high-tensile brass.

3. Disc brake capacity.: Maintain high torque for consistent usage.

4. Crossed Roller Bearing : High Rigidity.

5. Brake signal : 2 pieces of pressure switch ( made in Germany )

6. Solenoid Vales ; SMC ( made in Japan )

7. Copper worm gear : Made in Japan .

8. Highest quality of all components .

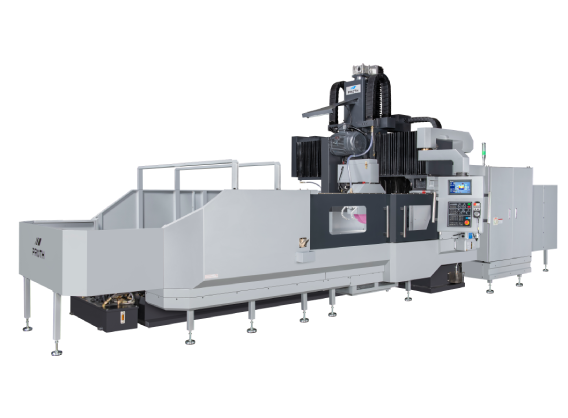

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Hydraulic System : Two single-acting hydraulic cylinders are used with their piston rods anchored at very specific positions.This enhances rigidity and creates a very stable table motion; table float is eliminated.

3. Grinding spindle : The precision high rigidity spindle is of a cartridge type design. This provides for easier accessibility and service when maintain is needed.

4. Upgradable CNC numerical control.

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.