Theme

Digital Transformation

Green Transformation

HAINBUCH GmbH

Product Description :

The HAINBUCH SYSTEM allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.

RAISE PRECISION CO., LTD.

Product Description :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

WEI FONG PRECISION CO., LTD.

Product Description :

LINT linear bearings have been wild applied in various uses with strict progress of produce, stable tolerance and good quality.

Applications: Machine tool, industry automation equipment, fitness equipment, smith machine, elliptical machine, printing press…etc.

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

CNC-TAKANG CO., LTD.

Product Description :

主軸低轉速、高扭矩,四段自動變速,適合重切削之零件加工。<br />

一體成型3山形床身,結構高剛性。<br />

<br />

強力型主軸箱,齒輪熱處理硬化、經高精密研磨處理,適合重切削與精密加工。<br />

4段變速系統,低速高扭矩輸出。<br />

9轉時即提供全馬力輸出。<br />

<br />

高強度床身一體成型,採用高張力米漢娜鑄鐵,經熱處理及研磨加工,硬度HS70度以上<br />

各滑動面皆貼上滑摩樹脂(Turcite B),配合基準研磨面,經手工刮花加工,提供精密的移動與定位精度。<br />

X軸工字軌橫向滑板、Z軸三”V”型滑軌,高強度高剛性設計<br />

全手工鏟花<br />

主軸箱、刀塔、尾座、導螺杆軸承座、床鞍、滑台皆手工鏟花,均衡的接觸面提供高加工精度以及高剛性重切削,有效提供產能以及穩定的產品品質。<br />

<br />

高強度尾座本體,回轉式尾座心軸。<br />

回轉式尾座心軸設計與CNC車床主軸相同,剛性高、適合重負荷與高精密度加工。<br />

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

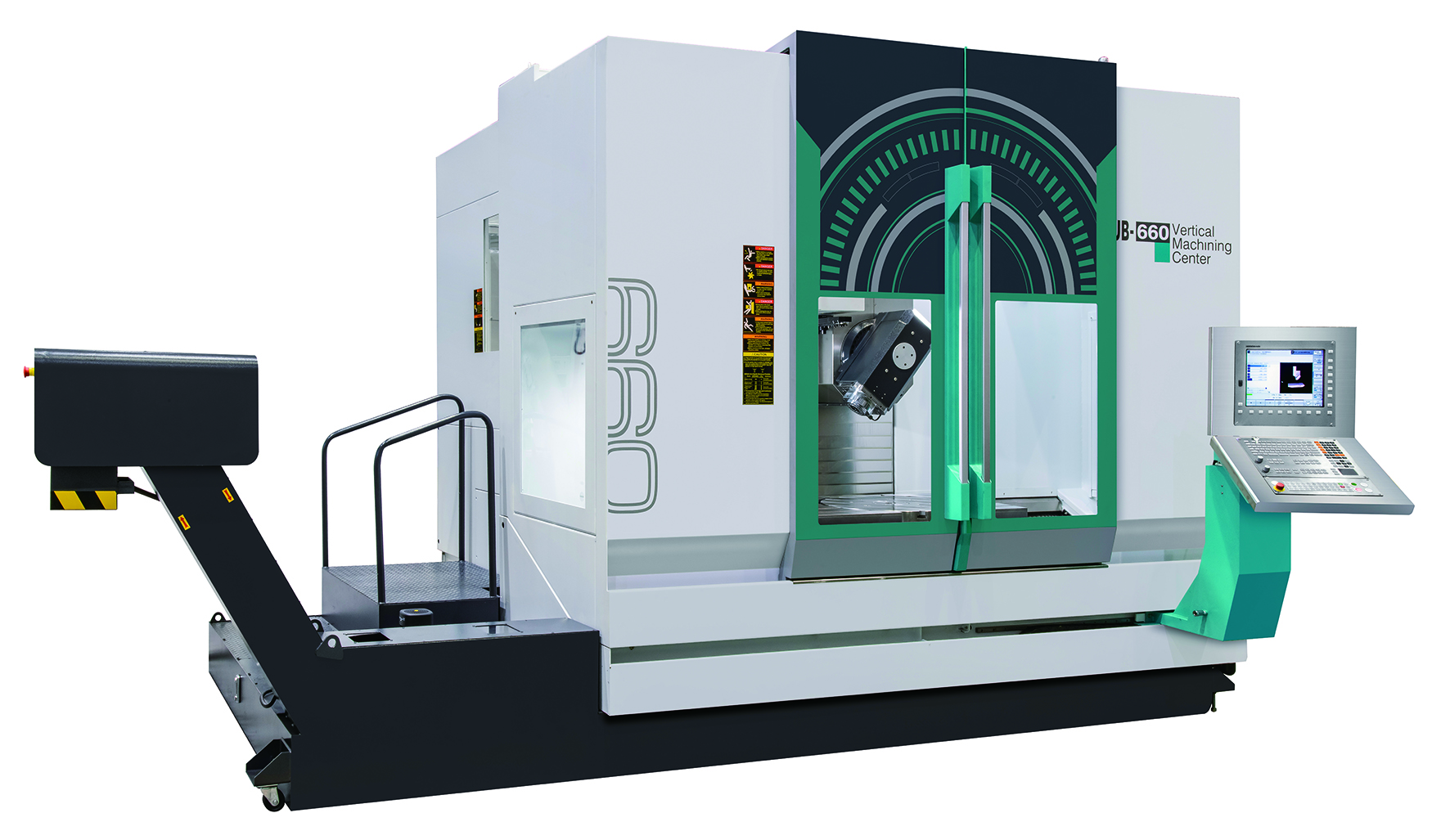

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.