Theme

Digital Transformation

Green Transformation

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

KAO FONG MACHINERY CO., LTD.

Product Description :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

KAO FONG MACHINERY CO., LTD.

Product Description :

5-axis synchronous machining of the KMU series can be used for multi-faceted processing of workpiece clamping positioning at one time or processing deep hole mold and inverted hook area.

Three-axis structure using box-type construction design, which can effectively improve the rigidity of the machine.

X / Y / Z axis with high rigidity roller type linear guideway, with high rigidity, fast moving, low wear and other characteristics, which can greatly enhance the processing dynamic precision and stability and effectively increase production efficiency.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

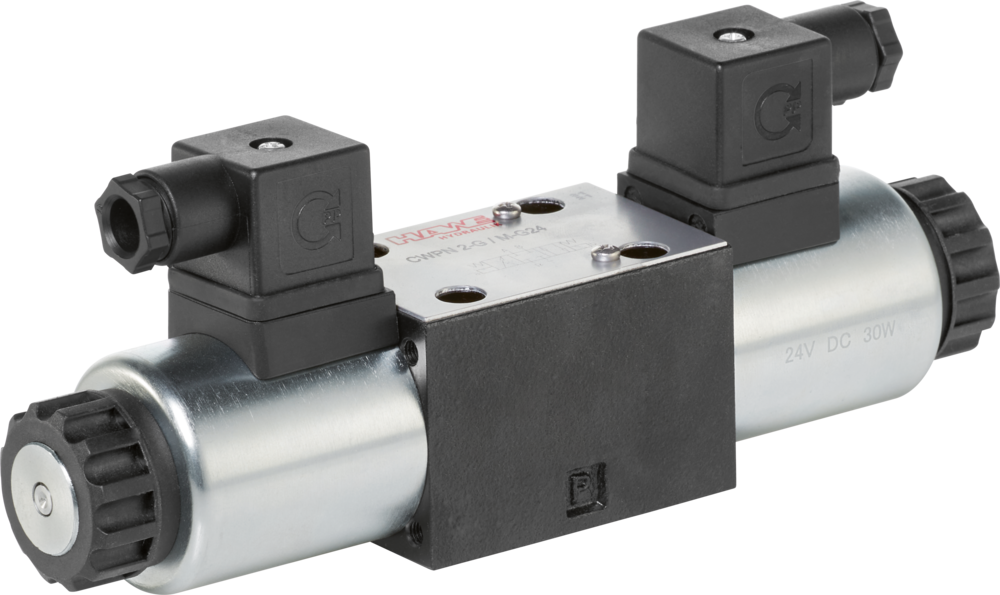

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

VISION WIDE TECH CO., LTD.

Product Description :

One of the proudest products of Vision Wide which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy. HF satisfies demands in mold surface cutting, angle cutting, 3D mold cutting, and precise contour finishing.

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The five-axis machining centers is suitable for high-efficiency, high-precision complex curved surface processing.

The characteristics of precise processing of complex workpieces and diversified manufacturing needs can be completed by fixing them in one setup.

The MV-500 shortens production working hours, improved the processing accuracy of complex parts to meet diversified needs, greatly saves on mold costs, and improves production efficiency and market competition.

GUANDA INTERNATIONAL MACHINERY CO., LTD

Product Description :

Specifically designed for steel beam / structural steel processing. STD 105 equips with 3 spindles working simultaneously. Each spindle works with a BT-40 ATC, which increases the working efficiency and flexibility.

We apply MQL (minimum quantity lubrication) not only to improve the working environment but also to reduce the operation cost.

We provide various automation solutions to meet your needs.