Theme

Digital Transformation

Green Transformation

G-TECH INSTRUMENTS INC.

Product Description :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

SUNG YANG MACHINERY CORPORATION

Product Description :

SAN YUAN Double Rail Wire Rope Hoist (Two Speed)

Three yuan double-track two-speed electric steel cable crane speed ratio

6 : 1 & 10 : 1.

The two-motor two-speed electric crane is designed as follows:

the fast/slow speed motor and the fast/slow speed brake are independent, and the fast/slow speed switching is performed by the clutch mode.

G-TECH INSTRUMENTS INC.

Product Description :

★POSITION INSPECTOR: Quick health check of your machine tool linear axis

★POSITION ANALYZER: In-depth analysis & diagnostics of your machine tool linear axis

★ROTARY AXIS INSPECTOR: Quick health check of your machine tool rotary axis

★ROTARY AXIS ANALYZER: In-depth analysis & diagnostics of your machine tool rotary axis

★SPINDLE INSPECTOR: Quick health check of your spindle accuracy & performance

★SPINDLE ANALYZER: In-depth analysis & diagnostics of your spindle accuracy & performance

DKSH Taiwan Ltd.

Product Description :

EVALED® RV F is the line of mechanical recompression evaporators designed to reach the highest level of reliability in heat transfer, with minimum impact in terms of fouling and scaling.

High efficiency forced circulation shell & tube heat exchanger with horizontal tubes allows wastewater concentration up to the salts solubility limits and to manage also suspended crystals.

Wastewater is constantly treated: the distillate and the concentrate are continuously separated and then simply discharged through a pump. Heat is recovered by cooling the two outlet streams using the inlet effluent.

Available in different materials to treat different effluents containing dissolved salty, organic compounds and even the most aggressive salted wastewater (high chlorides content), produced by various industries.

The MVR is the lowest energy consumption evaporation technology.

• Maximum water recovery;

• Effective reduction of waste to be disposed of;

• Modular and flexible;

• Intuitive HMI;

• Plug & play;

• Minimum labour.

SUNG YANG MACHINERY CORPORATION

Product Description :

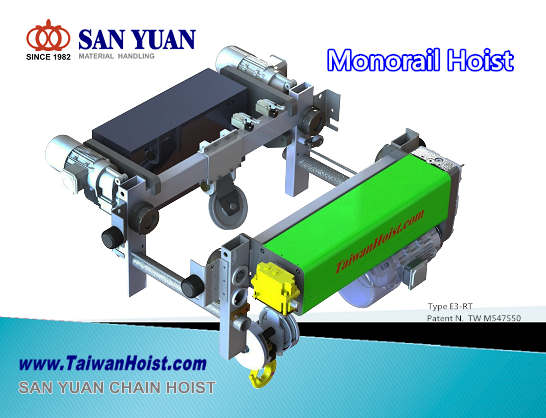

SAN YUAN Monorail Low Headroom wire rope hoist

●Hoisting Brake – disc brake having the braking torque >150%rated torque of motor .

●The brake is holden even if power failure - ensuring the load isalways stopped when the control button is released.

●Gears are smoothly operated for an oil bath lubrication and superior to a wear and abrasion resistance.

●Fine machining of the drum grooves minimizes wear on the rope, the return sheaves are resistance to wear.

DKSH Taiwan Ltd.

Product Description :

PC F series is designed to produce maximum distillate quality with minimum capital and operating costs. Each model is a compact skid-mounted unit, simple, safe and easy to move. Control is by a PLC, including the functions of feed and discharge, therefore allowing automatic operation and minimum supervision. All models are designed for continuous operation, 24h/day, and require just electrical supply and compressed air.

PC F series evaporators operate in a high vacuum condition, with the boiling chamber pressure set at 5-6 kPa (absolute vacuum), in order to save the thermal energy produced by the heat pump. In this way the boiling temperature of the wastewater is approximately 40°C (104°F) and typical phenomena (scaling, precipitation, corrosion) which may reduce the performance are either eliminated or considerably reduced.

From 0,7 to 24 m3/day – 0.13 – 4.4 US gpm of distillate

Dramatic reduction of volumes and disposal costs

Water reuse and matter recovery

TANKO ENTERPRISE CO., LTD

Product Description :

► Top tray for CNC tools

► 4"x2" PU casters with total 1000kg loading capacity

► T represents T drawer

► Normal Drawer: 90% extension with 100kg loading capacity

► T Drawer: 100% extension with 200kg loading capacity

► Drawer front height lower than 200mm with standard dividers

► Drawer front height over 300mm with CNC tools holder tray

► Full length aluminum handles with patented safety lock system

► Interlock system

G-TECH INSTRUMENTS INC.

Product Description :

To reduce damages caused by accidental collision, and to record collision events.

✓ Smart monitoring box consisting of sensors & electronics

✓ High bandwidth MEMS tri-axial accelerometer (X, Y & Z)

✓ Relay triggered in less than 1 millisecond upon a collision

✓ Built-in data log for max. 5,000 collision events

✓ Easy installation on machine structure

✓ Easy software for threshold setting & logging

✓ Economically priced

G-TECH INSTRUMENTS INC.

Product Description :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"