Theme

Digital Transformation

Green Transformation

EQP SERIES CO., LTD

Product Description :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design

G-TECH INSTRUMENTS INC.

Product Description :

★Multi-Channel Dynamic Measurement: 4-CH simultaneous analog input, compatible to accelerometer, microphone, etc.

★Digital Data Processing: Local real-time computing, data storage, and transmit to data center via ethernet.

★Test & Measurement : Remote Mode--FFT Analyzer;Standalone Mode--Data Recorder & Transmitter.

★Condition Monitoring: Programable multiple I/O interface, connect to controller for intelligent manufacture.

G-TECH INSTRUMENTS INC.

Product Description :

A rotor that does not perform dynamic balance correction may produce unnecessary vibrations and thus reduce the productivity of the machine, as well as damage to the bearings. At the same time, it may cause damage to the outer frame or supporting device and foundation during severe movement.

G-Tech HJ-4250S-A Hard Bearing Balancing Machine is applicable for tool machine spindles, high-speed built-in spindles, motor rotors / motors, rollers, fans, centerless grinding wheels.

A maximum rotor weight of 500kg, a maximum rotor diameter of 1 meter, and measurement accuracy at low speed dynamic balance is 0.5gram-mm(max), and the can be 0.05gram-mm(max) at high-speed dynamic balance.

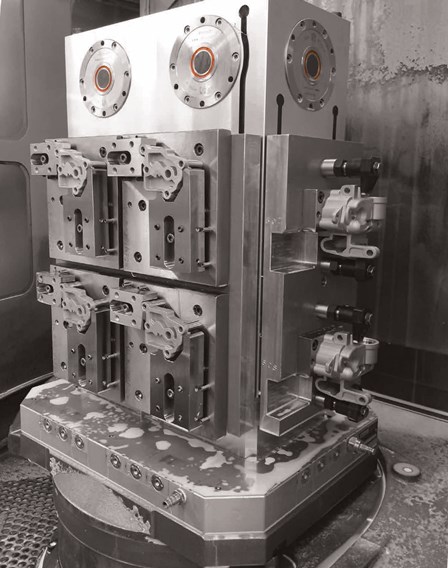

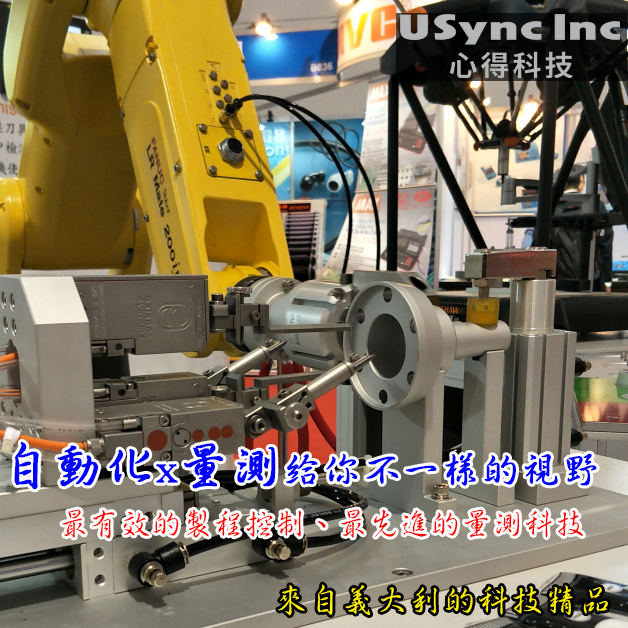

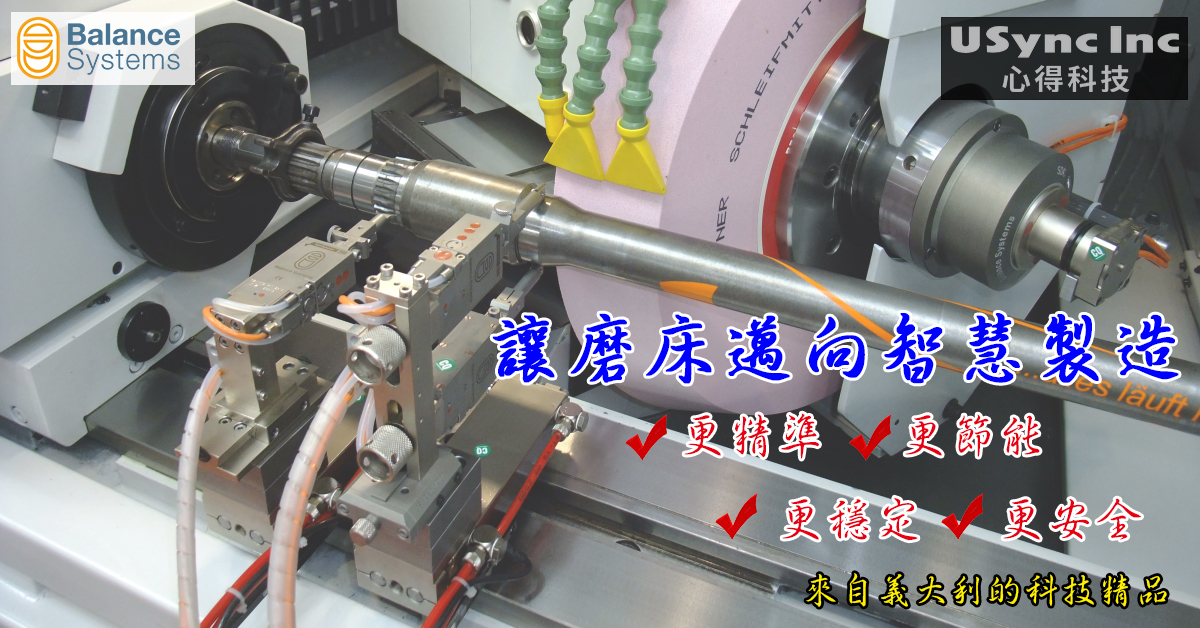

USYNC INC.

Product Description :

"VM25" is a high-performance application of a fully modular system designed for grinding machines, including automatic balancing on the 1 and 2 sides of the grinding wheel spindle, the use of audio detection to control the contact of the grinding wheel to the workpiece or sand, online Measurement and off-line measurement (absolute or relative) and other functions.

"B-Safe" can provide vibration and temperature information of the main shaft to detect and monitor the status analysis of the main shaft and machine. It is a new thinking product for intelligent monitoring. Its miniaturized volume design helps to install directly on the main shaft, ensuring that it can provide immediate monitoring of abnormal operating conditions, further predicting the timing of maintenance and failures, protecting your machine and reducing downtime.