Theme

Digital Transformation

Green Transformation

FUI JET TECH CO., LTD

Product Description :

The zero-point positioning system is a normal clamping mechanism, which is opened during ventilation and the air pressure is cut off. When the zero-point positioning system is ventilated, the pressure will pass through the compressed spring inside the piston, causing the piston to rise, and the steel balls can retreat toward the water pump. When the air source is turned off, the spring will push back the piston, and the piston handle will The steel ball is pushed toward the middle, causing the ladder bolt to

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Realistic CNC Controller Function Panel, Modularized Machine Operation Panel, and Machine Simulation.

Excellent tool for CNC controller recognition and practicing tool offset.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time.

Excellent tool for learning CAD/CAM and verifying with simulation.

BUFFALO MACHINERY CO., LTD.

Product Description :

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.

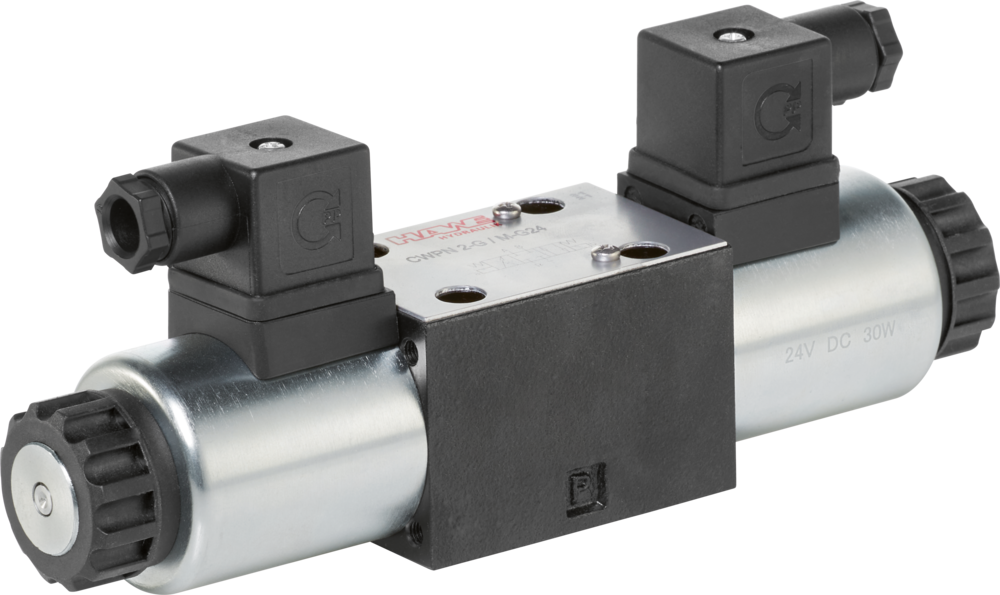

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

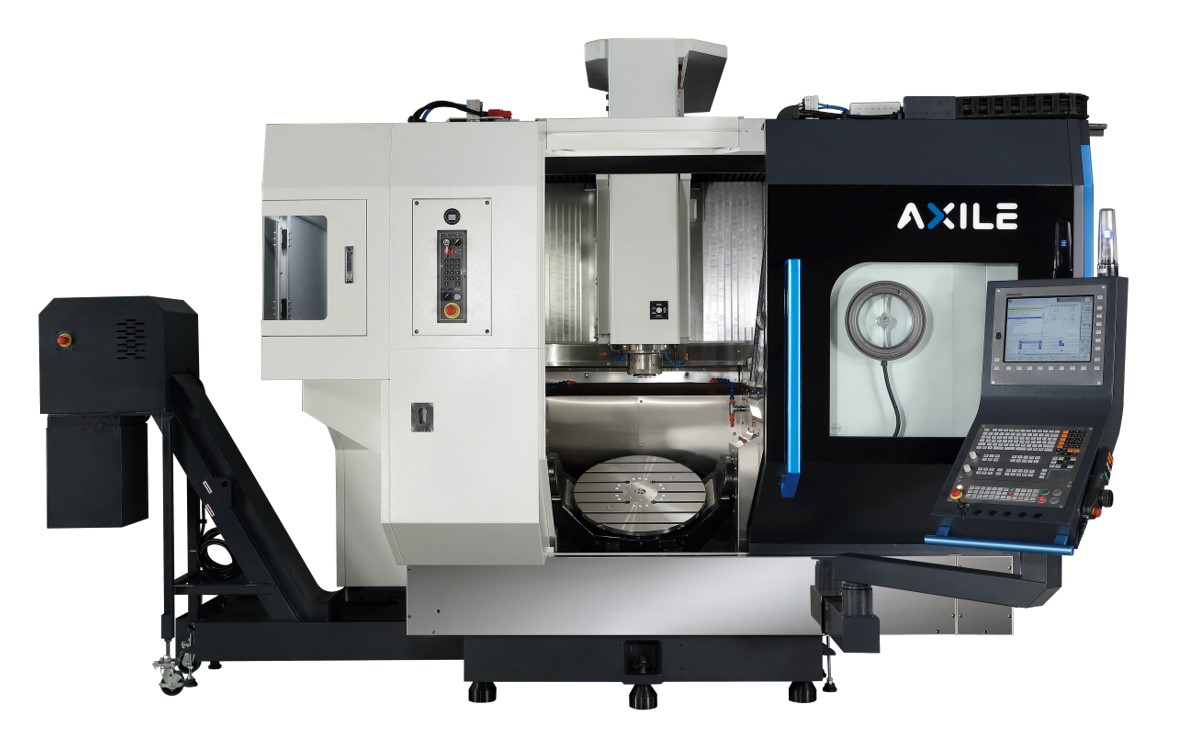

BUFFALO MACHINERY CO., LTD.

Product Description :

The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a maximum table loading weight of 2.5 tonnes and maximum diameter of 2,200 mm X 1,200 mm, the DC12 takes on the larger, heavier parts common in the aerospace, power generation, and die and mold industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the D12 is capable of deep cuts and complex contouring while maintaining utmost precision.

With larger workpieces come more chips, meaning the DC12 features excellent chip removal efficiency, to prolong tool life and ensure no residual interference. Therefore, the DC12 delivers the high surface quality expected by leading manufacturers.

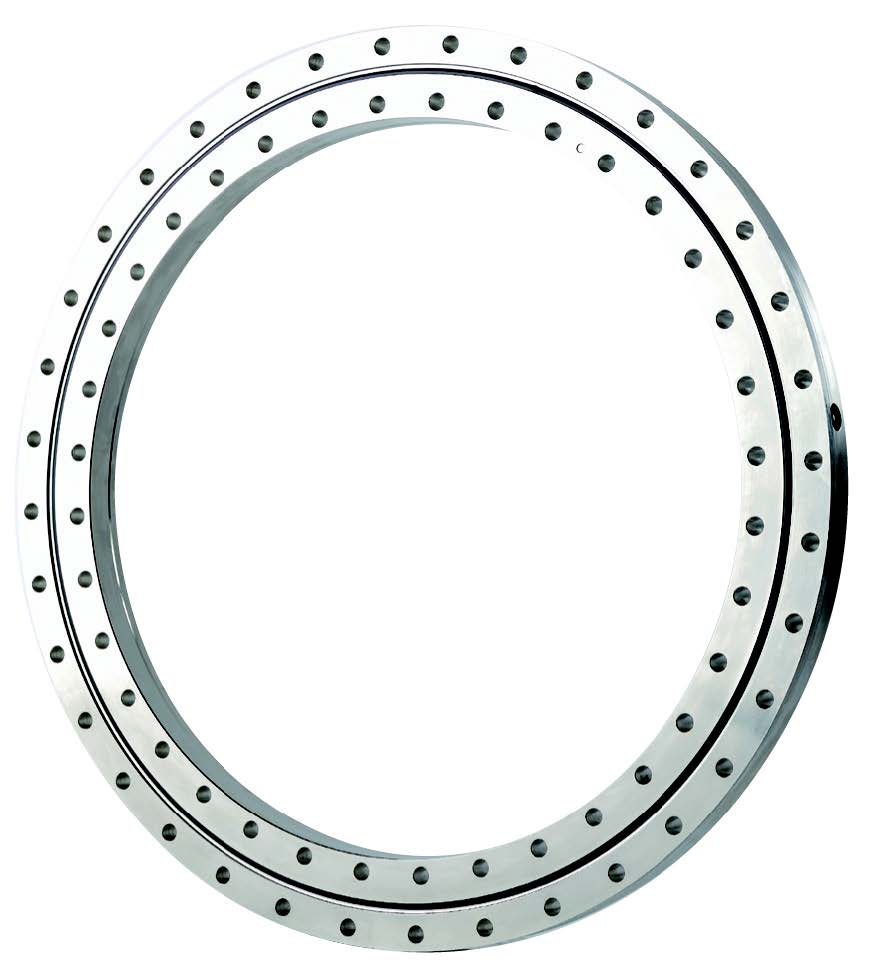

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

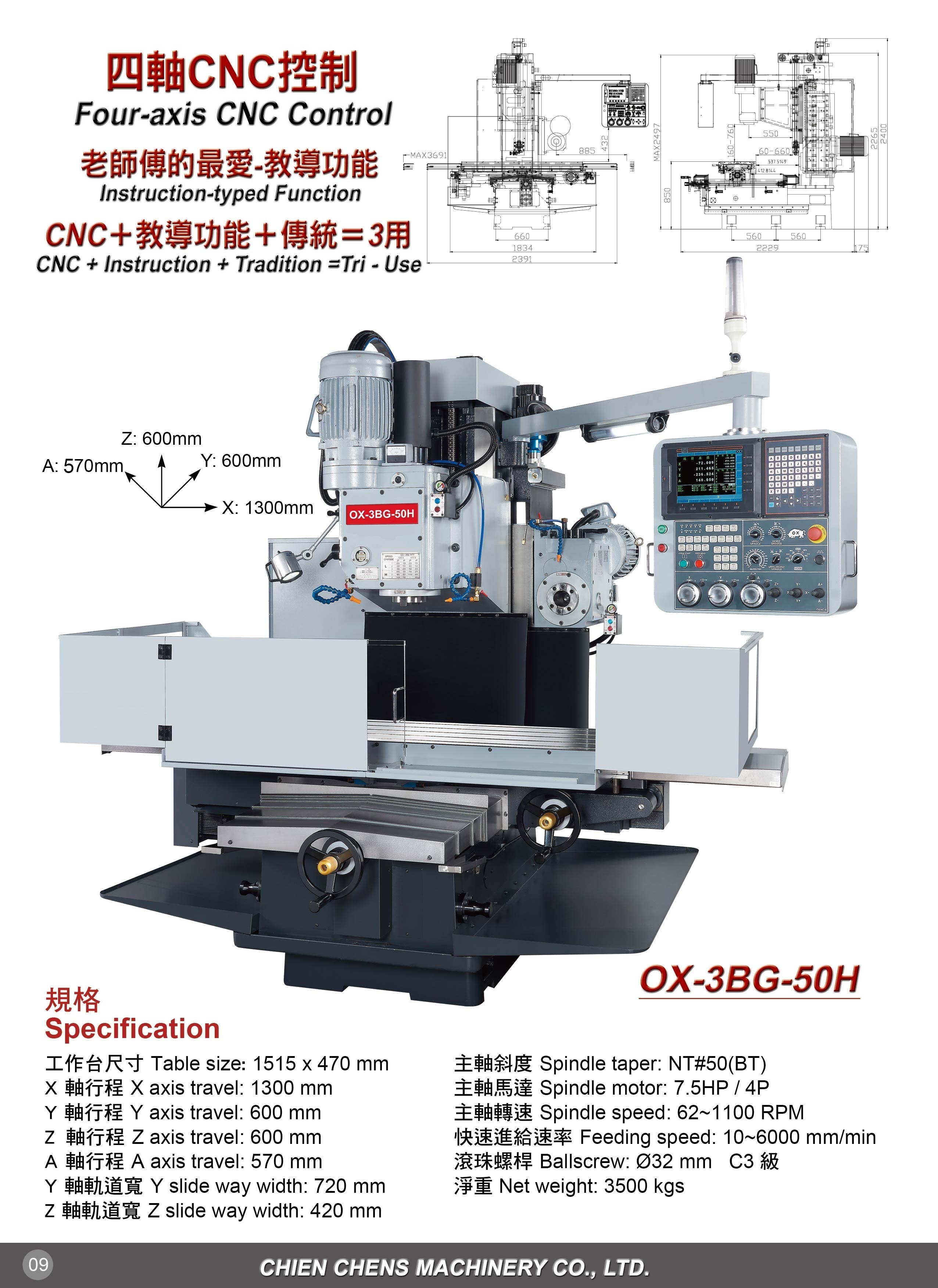

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 760 mm

Z Slide way width: 420 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 2P

Spindle speed: 62~1100 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3200 kgs

JIUH-YEH PRECISION MACHINERY CO., LTD.

Product Description :

1.以「電子式MPG」自動化技術、減少誤動作、節省人力

2.MPG微量進給,高精密、高效率之滾珠螺桿,及伺服馬達

3.人機介面之設計

4.立臥兩用雙主軸一體式結構設計

5.主軸溫升防護系統、潤滑油冷卻循環裝置加上非接觸式與迷宮式路徑結構設計

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.