Theme

Digital Transformation

Green Transformation

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

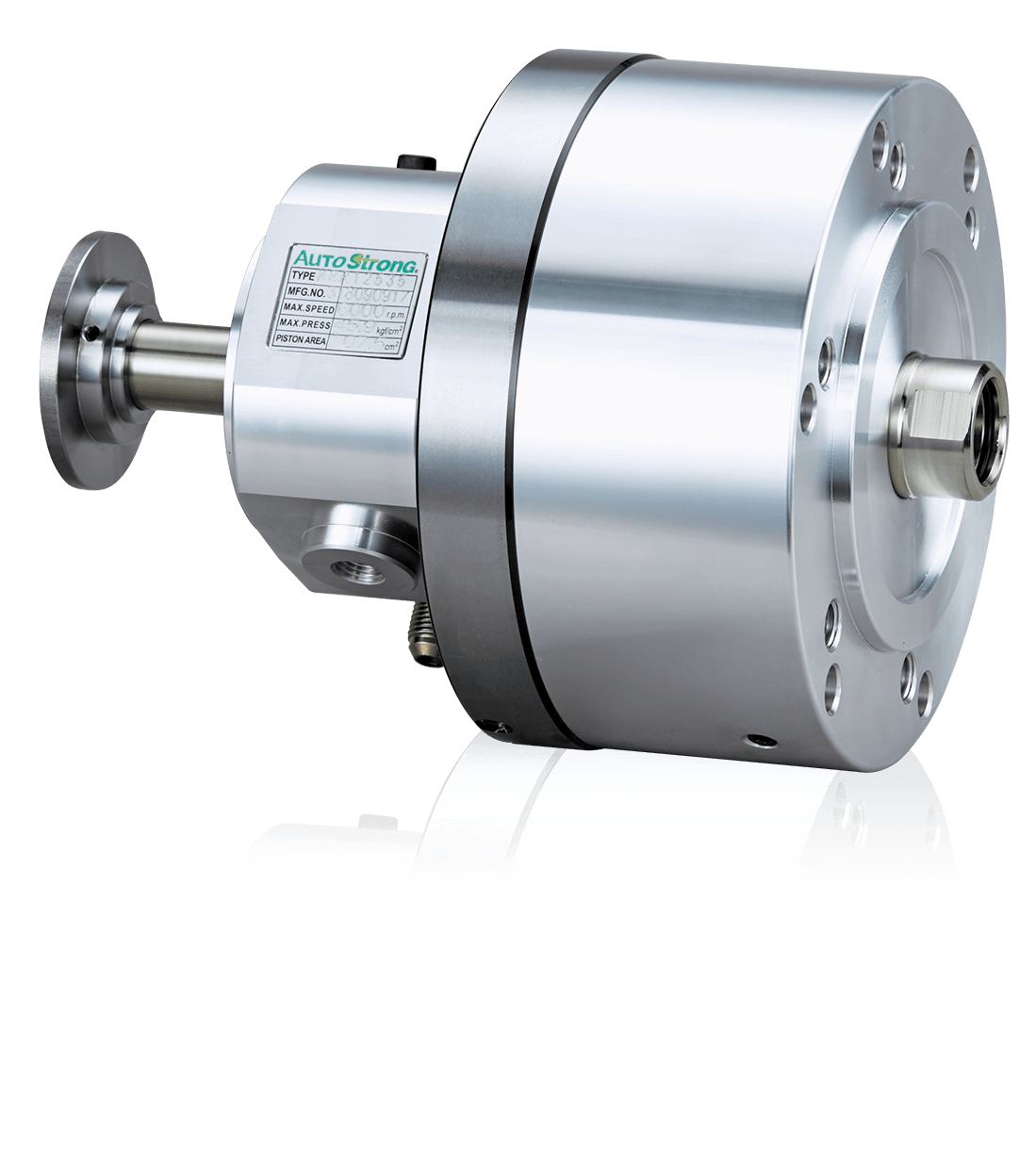

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLKA series is using the optimal designation, so the clamping capacity is higher than other cylinders. The cylinder body and the fulcrum are integrated structured. Therefore, the cylinder’s size is smaller and it’s more solid and firm.

Clamptek’s CLKA series uses special dust seals to ensure the high dust proof and high sealing performance. As for the lower flange part, which uses minimized designation, it’s suitable for the compact and light fixture.

If you have any customized requests, please feel free to contact us.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

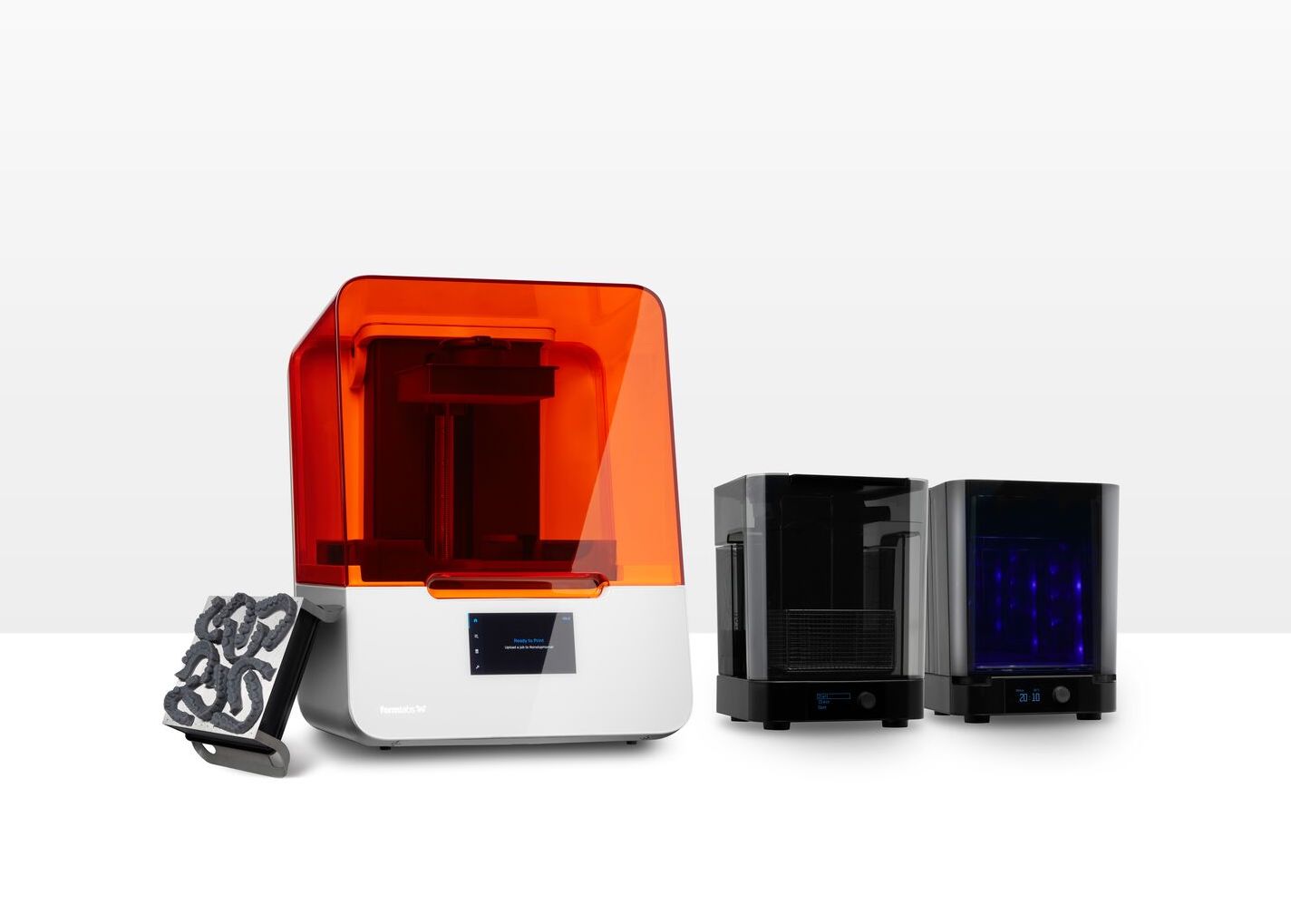

Taiwan TeamA Tech. Co., Ltd.

Product Description :

formlabs 熱銷光固化機種 Form 3+/3B+ 搭載專利研發「低應力光固化成型技術(LFS)」,其特色包含彈性樹脂槽與封閉式光學模組(LPU)等,雷射光可垂直照射到物件,大幅增加機器的可靠與穩定性,可印出高精確度、平滑度及透度更佳的高品質物件,桌面級的機種,也能達到工業級的效果。

搭配上為 Form 3+/3B+ 量身打造的後處理設備-自動清洗機 Form Wash 及恆溫光固機 Form Cure,提供完整、快速的 3D 列印製造流程。

Form 3+ 六大特色包括:

1. 前所未有的表面精細度

2. 極平滑的物件表面與透度

3. 彈性樹脂槽使成功率大增

4. 遠端列印超easy

5. 無與倫比的30多種多元樹脂材料

6. 輕觸支撐材帶來最佳效率

HOMGE MACHINERY IND. CO., LTD.

Product Description :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.

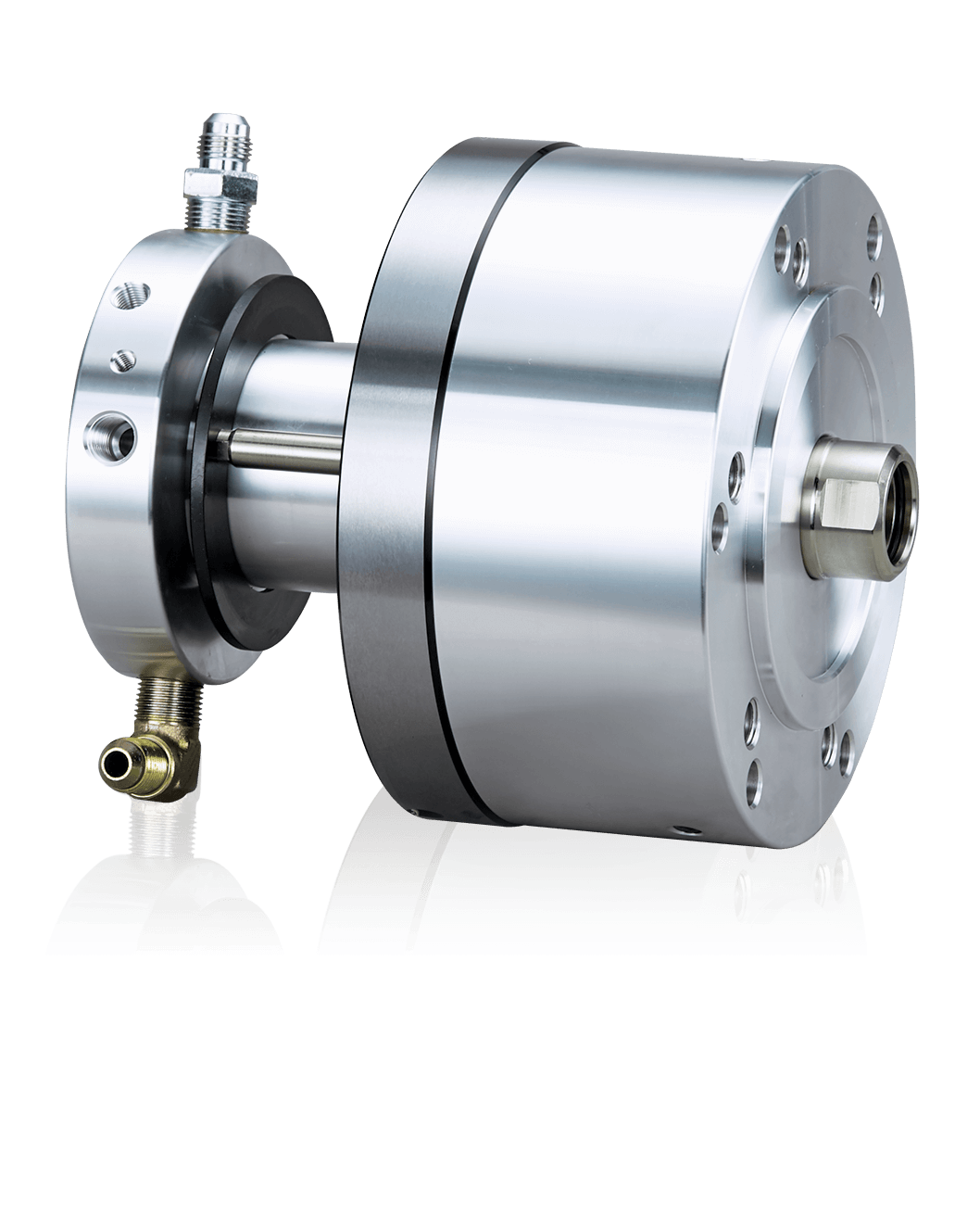

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

Clamptek’s CLF5H series designed with connecting rod structure which can operate conveniently. CLF5H series can also reduce the interference with loading and unloading operation, because when CLF5H series is in the unclamping state, it’s clamping arm can be put lower than holding position.

Clamptek’s CLF5H series’ clamping arm is very flexible. By reducing the interference of the surrounding equipment, CLF5H series can save lots of working space.

Clamptek’s CLF5H series equipped with special dust proof design and high sealing, which can prevent the cutting chips and coolant to infiltration. Therefore, CLF5H series can be used in more severe conditions.

Please kindly check the suggested operating pressure as below,

Max. operating pressure: 70 kgf/cm2

Min. operating pressure: 10 kgf/cm2

YOKE INDUSTRIAL CORP

Product Description :

1. 360° rotation and 230°pivot

2.Rotatable under load due to its unique ball bearing design.

3.Manufactured in accordance with EN1677‐1 and the requirements of ASME B30.26

4.Certified by DGUV GS‐OA‐15‐04

5. Forged alloy steel, quenched and tempered

6.With the Grade 100 High‐strength alloy steel, WLL is increased without increasing swivel size compared to other Yellow Point models.

7.4:1 Design factor

8.100% Magnaflux crack detected

9.Proof load at 2.5 times the WLL

10.Fatigue rated for 20,000 cycles at 1.5 times the WLL