Theme

Digital Transformation

Green Transformation

PRAISE PRECISION IND. CO., LTD.

Product Description :

NEW PRODUCT- CUTTING KNURLING TOOLS USED ON LATHE

Method of forming knurling

1. Press forming(Form knurling)

Press knurling tool directly to workpiece in turning on the lathe

to form the patterns. Pressure is applied to the lathe spindle, and the outside diameter of workpiece will become bigger

2. Cutting forming(Cut knurling)

The knurling tool is applied to workpiece just like cutting, less pressure

to lathe spindle and less machining resistance, forming a clear patterns, the best choice for using on CNC lathes

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

※ We design and manufacture "speci c industry" tools

with fast delivery and great quality.

※ It can be designed according to the highest standard

and speci cation from customers. Flexible manufacturing

and accept customized tolerance.

※ From concept to nal completion. JLC customized

tools will reduce the cutter exchange labor time and

improve the e

ciency of mass production.

JIN LI CHENG CUTTING TOOL CO., LTD.

Product Description :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

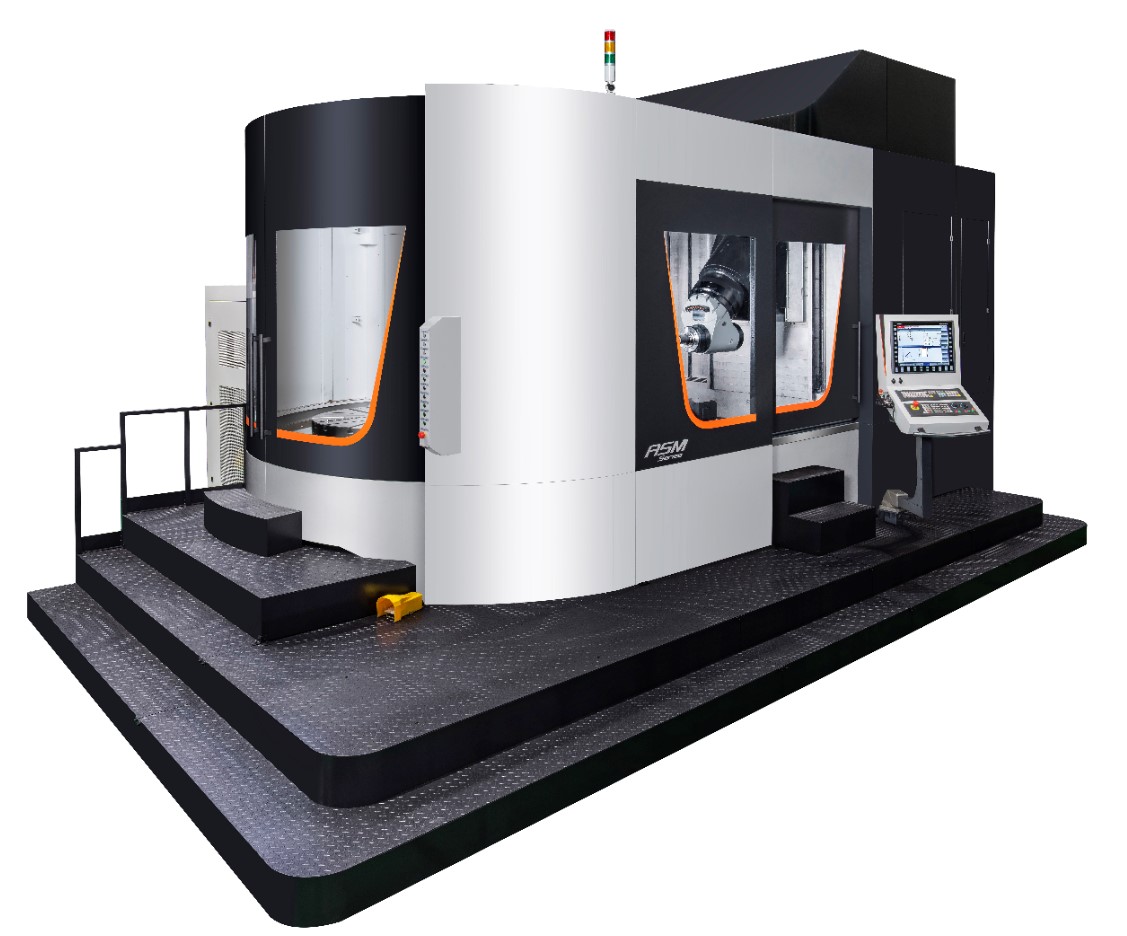

VISION WIDE TECH CO., LTD.

Product Description :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

VISION WIDE TECH CO., LTD.

Product Description :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

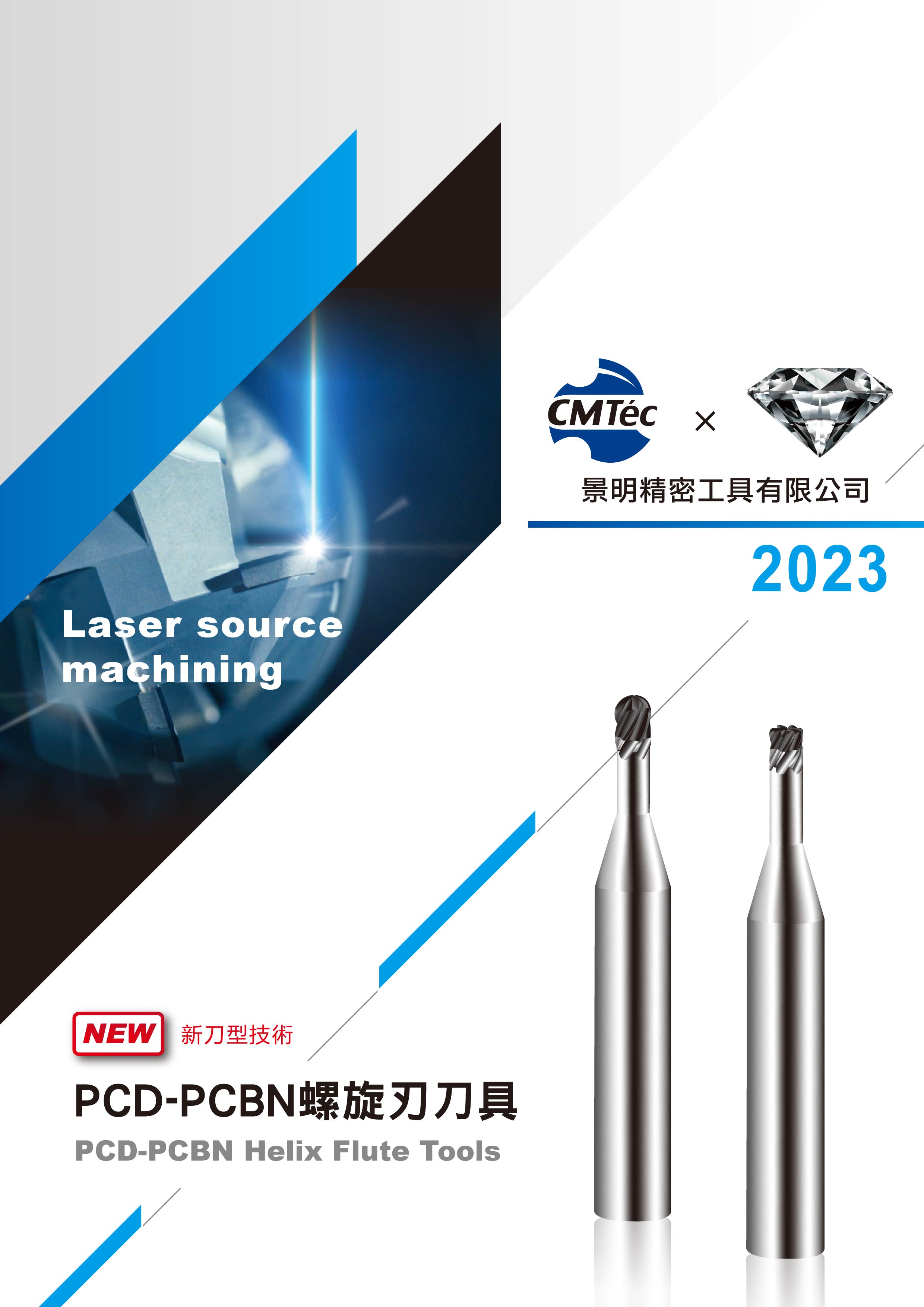

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

For Ultra-Hard Material Machining

(For Carbide, SiC, Al2O3, Si3N4 and ZrO2 Machining.)

------------------------------------------------------------

PCD Helix Flute End Mills- Multi-Flute:

★ Multi-flute decreases cutting resistance and makes high efficiency.

★ Applies to high precision machining of carbide and ceramics.

PCD Helix Flute Drilling:

★ For carbide, ceramics, aluminum, copper, graphite and carbon fiber drilling.

PCD Ball Rolling Cutter:

★ Special cutting edge and high accuracy R of ±0.005mm realize high quality mirror polished machining.

★ Applies to carbide and hardened steel(≦70HRC) mirror polished machining.

PCBN Helix Flute End Mills:

★ For hardened steel(HRC45~65°) and powder metallurgy machining.