Theme

Digital Transformation

Green Transformation

YING HAN TECHNOLOGY CO., LTD.

Product Description :

5-AXIS VERTICAL MACHING CENTER BELONGS LINEAR WAYS ON THREE AXES, X, Y, Z -AXIS TRAVEL: 800x600x550mm, MEEHANITE CAST IRON IS TEMPERED FOR STRESS RELIEF TO ENSURE STRUCTURAL STABILITY WITHOUT DEFORMATION. REINFORCED COLUMN BASE GREATLY INCREASES STRUCTURAL STRENGTH AND WILL EXHIBIT ULTRA-HIGH STABILITY DURING HIGH SPEED OPERATION. WITH THE EQUIPMENT OF CNC TILTING ROTARY TABLE, THE MACHINE IS ABLE TO PERFORM 5-AXIS MACHINING, IT CAN MACHINE COMPLEX, MULTI-SIDED PARTS IN A SINGLE SETUP, THEREBY REDUCING SETUP TIME WHILE INCREASING PART ACCURACY.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

MATECH INDUSTRIAL CO., LTD.

Product Description :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Cutting Tools

* Applications|Automotive Parts, Aerospace Industry

Customized turning tools, end mills and reamers with special cutting edge treatment can divide swarfs into smaller pieces to avoid swarf tangling and residue inside the workpiece. They can meet various mass production and customization requirements (workpiece finish, etc.).

* Processing Material | Aluminum, copper, cast iron, alloy steel and other materials

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

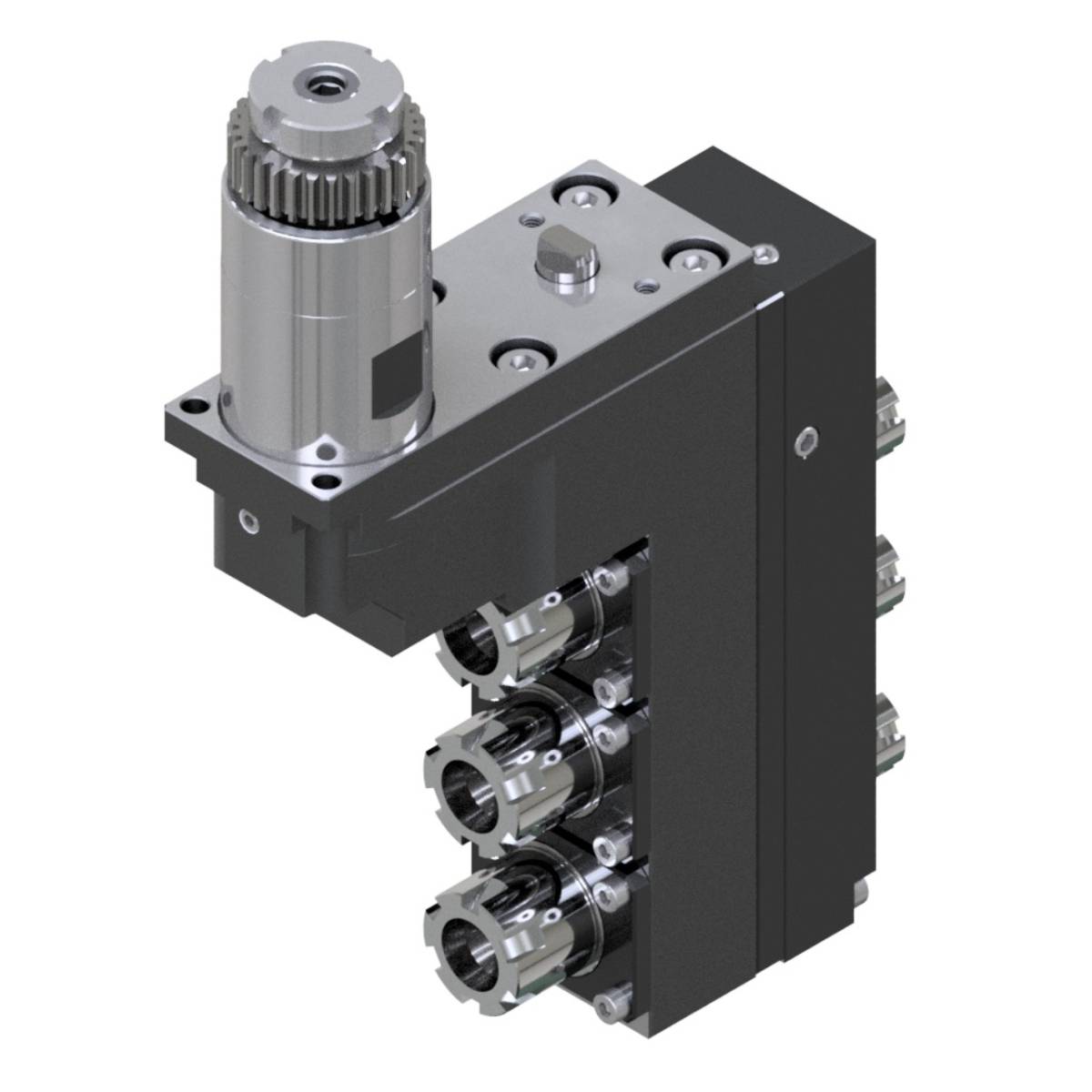

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed for precision complex parts processed in one setup.

Power & Versatility: It has Double Spindles and Turrets with back machining provided by an 8-station sub-turret and sub-spindle with a total tool capacity of up to 32 tools. This solution is a powerful combination of power, precision and versatility.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: VDI 25 8-Stations Sub-Turret, 3.7/5.5 kW Spindle Power, 48 mm Through Hole.

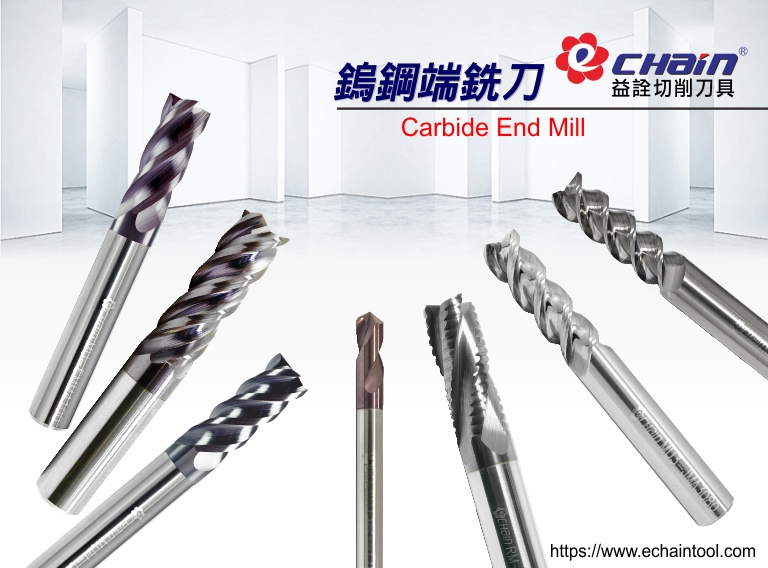

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"