Theme

Digital Transformation

Green Transformation

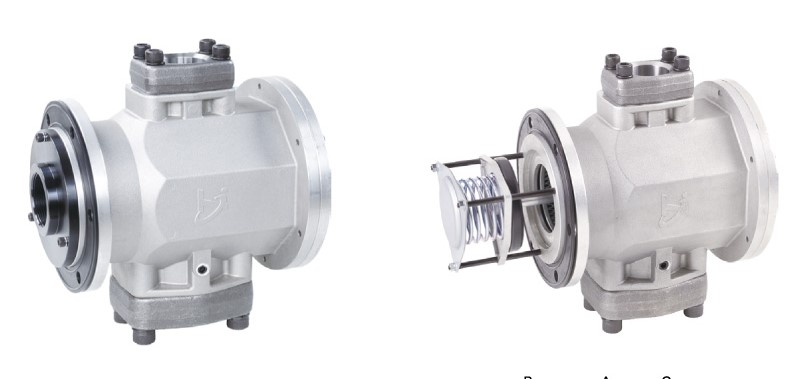

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

In order to solve the problem of difficult cleaning, the market developed so-called box-shaped filters, but still can not completely solve

1 takes up too much space

2 Multiple pump combination systems must be configured one-to-one, resulting in too many connectorsProne to oil leakage

In order to solve the above problems, the company has developed a pair of two-box external magnetic flange filters to reduce space and prevent oil leakage problems, reduce assembly time and parts costs

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

Product Description :

The oil return filter is mainly installed on the oil return line of the hydraulic system. Various impurities such as abrasive particles generated during the work of various hydraulic components can be blocked by setting the oil return line to filter and avoid returning to the tank again.

HC FENG CO., LTD.

Product Description :

FOODIE (Chip/Sludge Removal Machine) works for :

Filtration/Removal of excess components

Chip/Sludge Removal

Fine Chip Removal

No downtime

No consumables

Backwater automatically & simultaneously

Air pressure drive w/o a plug

Vertically fast filter drying up to 90% efficiency

Precision filters effective up 20% for super filtration micro-fines

Easy to move

Filter accuracy can be adjusted

Extend cutting fluid life

HC FENG CO., LTD.

Product Description :

4 in 1 Coolant Purification System

1. Filtering floating debris and dirty particles

2. Oil/Water Separation, removes tramp oil down to 5% water content

3. Ozone Disinfection, eliminates bacteria and cleaned fluid backflow

4. Automatic control panel and pH detect device

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

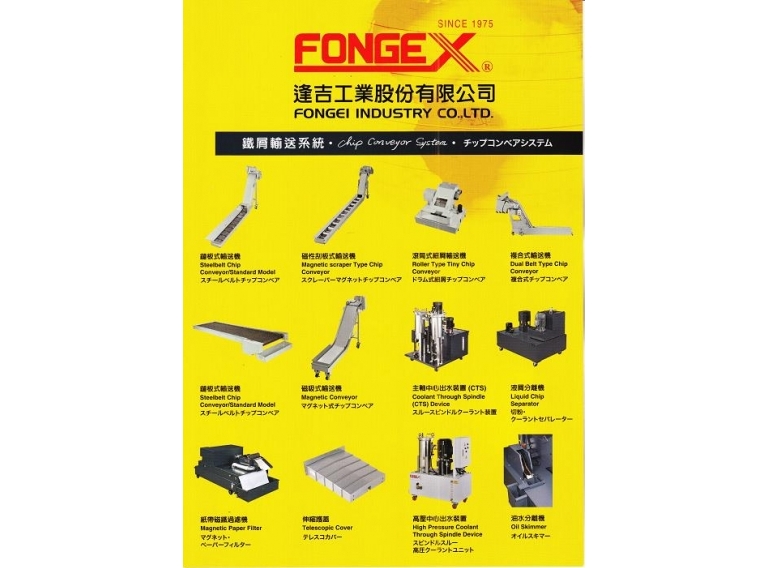

FONGEI INDUSTRY CO., LTD.

Product Description :

Steelbelt Chip Conveyor/Magnetic scraper Type Chip Conveyor/Roller Type Tiny Chip Conveyor/Dual Belt Type Chip Conveyor/Magnetic Conveyor/

Coolant Through Spindle(CTS) Device/Liquid Chip Separator/magnetic paper Filter/Telescopic Cover/High Pressure Coolant Through Spindle Device/Oil

Skimmer

FONGEI INDUSTRY CO., LTD.

Product Description :

-It can process various chips created by complex machining.

-Equipped with a filter system for processing cutting fluid with 0.5mm filtrating accuracy.The roller filter screen features a self-cleaning function to ensure the dependability of filtration.

-Equipped with an industry-leading overload protection device the extends the parts service life of the chip conveyor.