Theme

Digital Transformation

Green Transformation

GUEY CHERNG TRADING CO., LTD.

Product Description :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

🔹The optimized design of the accessories of CHA / CHA-P series makes the structure more compact and increases the product strength.

🔹 CHA / CHA-P series equipped with special dustproof design and have high sealing performance.

🔹The designation of high anti-torque makes the durability long.

🔹 Max. operating pressure:70 kgf/cm²

Min. operating pressure:15 kgf/cm²

🔹Double acting

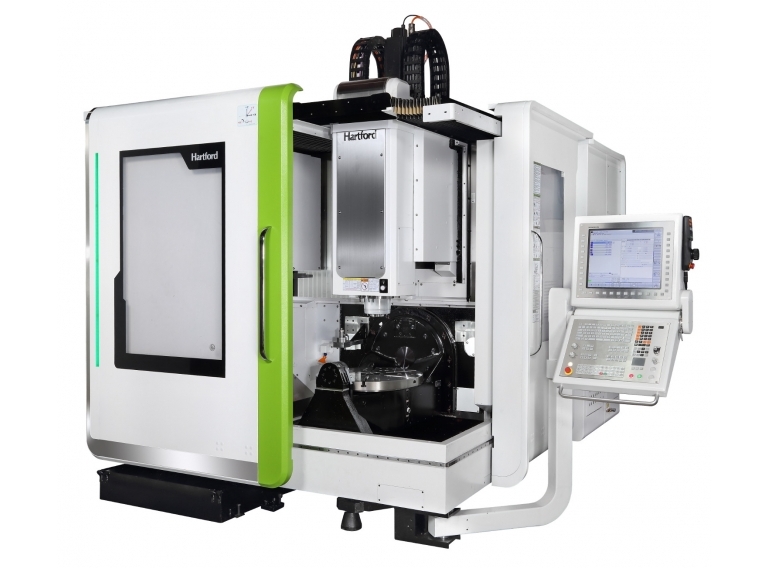

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

ROYAL PRECISION TOOLS CORPORATION

Product Description :

Driven by built-in motor:

▶High speed

▶High precision, high efficiency

▶High dynamic rotary accuracy

▶Balancing adjustment within G1, low vibration

▶Modularized easily

▶Thermal displacement, high stability

▶Short overall length, low inertia

▶High motor power, high moments of inertia

Driven by belt:

▶High dynamic rotary accuracy

▶High axial & radial rigidity

▶Stable thermal temperature

HONG JI PRECISION MACHINERY LTD.

Product Description :

Drilling capacity is from Ø5mm to Ø40mm and the max. drilling length is 3000mm

The machine is suitable for drilling accessories of petroleum system, tube holes of heat-exchangers, long mechanical sleeves and long aerospace parts.

Slideways of all axis are harden box ways with heat-treatment to HRC52, this design has good damping to absorb vibration as drilling big and long holes.

The worktable is loaded on the harden box slideways with width 200mm. The max. loading weight on the worktable is 20tons.

The width of column is 2 meters with two sub-columns to provide the excellent support to Y-axis as moving up and down. Total weight of the machine is about 38tons.

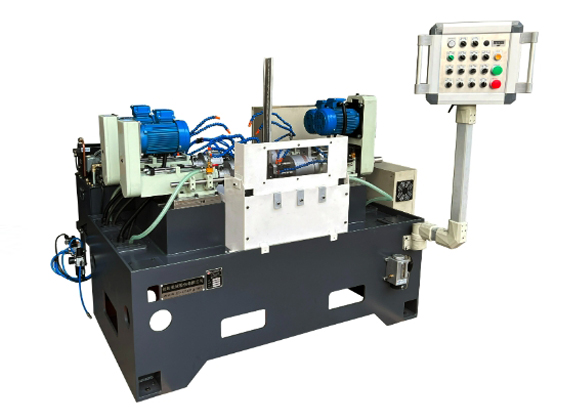

YI CHANG MACHINERY CO., LTD.

Product Description :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!