Theme

Digital Transformation

Green Transformation

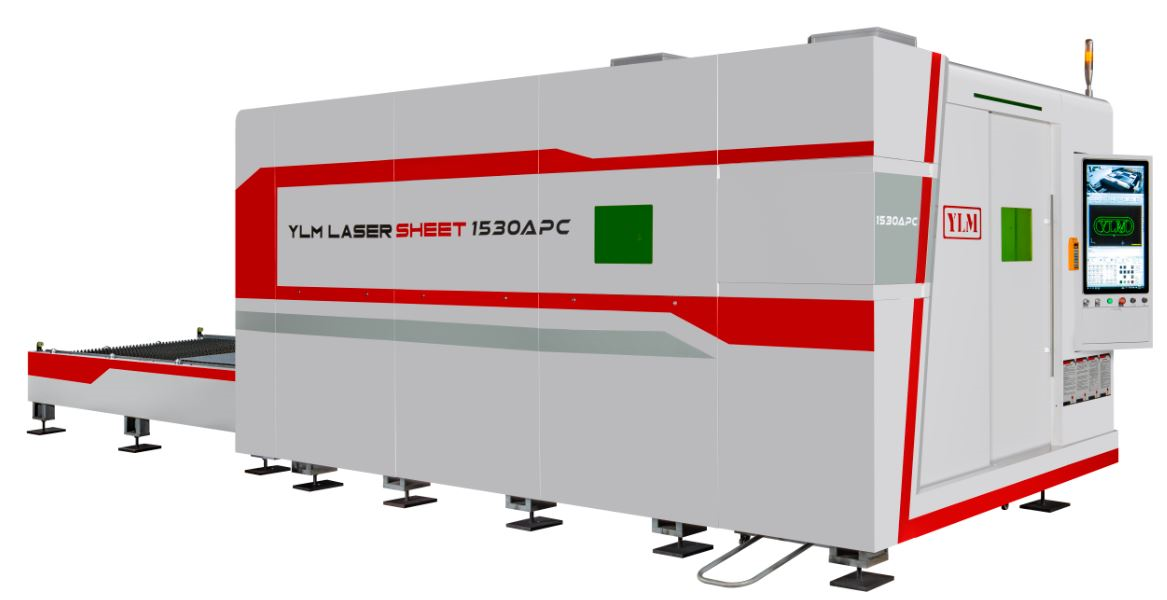

YING HAN TECHNOLOGY CO., LTD.

Product Description :

Suitable for cutting various metal sheets

■Maximum cutting thickness of metal sheet varies with the laser power.

■Upon customer request, the machine can be designed with a work piece platform as mechanism(optional). It helps to reduce work piece loading/unloading time, which in turn upgrades operation efficiency.

■Large laser power, high efficiency and high productivity.

■Equipped with an intelligent digital controller featuring humanized control, which is easy to learn and operate.

■The specially designed software allows the operator to design the graphs on characters with ease, then machining can be conducted immediately.

■Enclosed splash guard

■Fast machining, power saving, outstanding safety protection, low trouble and easy maintenance.

For cutting commonly used metal sheets such as:

■Carbon steel sheets

■Alloy steel sheets

■Galvanized steel sheets

■Stainless steel sheets

MATRIX PRECISION CO., LTD.

Product Description :

GVP-8040 applies the FANUC controller and high speed grinding spindle, through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The machining workpieces include involute gears, large-module hobs and cycloidal gears, the high-efficiency and high precision expressed from the products are equivalent to worldwide top brand’s ones. GVP-8040 is your best choice.

MATRIX PRECISION CO., LTD.

Product Description :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

■The specially designed software allows the operator to design the desired graphs on characters with ease, then machining can be conducted immediately.

■The automatic height adjustment function enables the focal length to be maintained at a constant status, thus ensuring the consistency of cutting quality.

■Small heating area on the workpiece eliminates workpiece deformation problems.

■This machine is equipped with a constant temperature water chiller, enabling the machine to withstand long time continuous running with stable performance.

■The enclosed splash guard can prevent damage to personnel due to the strong laser light.

■The shortest cutting tail is ≥0 mm.

Taiwan Auto-Design Co.

Product Description :

// SolidMEN-300的優點

✅ 材料: 不綁材料僅建議合格廠商,未來可自行選用適合材料

✨ 雷射: 德國 500W 水冷式雷射穩定性佳

⚡ 層厚: 層厚可控範圍 10~100μm (最小進給單位 10μm)

🛠️ 成品: 可列印多種金屬材料,強度超過鑄造,可作為表面後處理及拋光使用

🔬 研發: 不綁參數開放製程研究,未來材料無受限可自行開發

⬆️ 尺寸: 300x300x300 可製作大尺寸工件,另有機型可增大或縮小

💎 緻密度>99.5%,品質優於鑄造,近似鍛造

🤖 搭配遠端資訊與智能化視覺模組,方便製程穩定性及智慧化整合。

(即時錄影、列印層數/高度、雷射功率、粉未剩餘量、腔體含氧量、製程時間等)

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

JEFFER MACHINERY CO., LTD.

Product Description :

This machine comes in a one-piece construction that has been heat-treated to achieve maximum rigidity. The rails are thermal treated and precisely ground to reach hardness of more than HRC 60˚. Furthermore, options are available to adopt rails of various lengths to meet different knife grinding requirements. The machine length can be customized for specific needs from 1,600 to 4,000mm. Rough and finish grinding wheels can be controlled manually and automatically. The minimum grinding wheel downfeed amount is 0.005mm and the spindle is equipped with an automatic cooling system which ensures excellent cooling effect. The SSG-8 employs an automatic lubrication system for smoother operation and longer service life.

SSG-8 Feature :

1. Knife tools movement type.

2. After grinding by coarse wheel and fine wheel, knife

tools can be sharp.

3. Force cooling system on motor shaft obtains better

cooling effect for the knives.

4. Grinding wheel lifting seat is used by ball bearing screw,

it can adjust up and down movement in precision.

5. Water splash guard and coolant tank are made of

stainless steel.

6. Grinding Capacity (Magnetic Chuck) LxW :

2500x200mm