Theme

Digital Transformation

Green Transformation

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The five-axis machining centers is suitable for high-efficiency, high-precision complex curved surface processing.

The characteristics of precise processing of complex workpieces and diversified manufacturing needs can be completed by fixing them in one setup.

The MV-500 shortens production working hours, improved the processing accuracy of complex parts to meet diversified needs, greatly saves on mold costs, and improves production efficiency and market competition.

NUMEN MACHINERY CO., LTD.

Product Description :

*High-rigidity structure design, using C3 precision ball

screw for axial feed and direct drive with servo motor.

* X/Y/Z axes installed with roller type of linear slide way

to ensure rigidity of axial movement and fast feed rate.

* Direct drive spindle.

* Suitable for various processing industries.

* 4th axis / 5th axis applications.

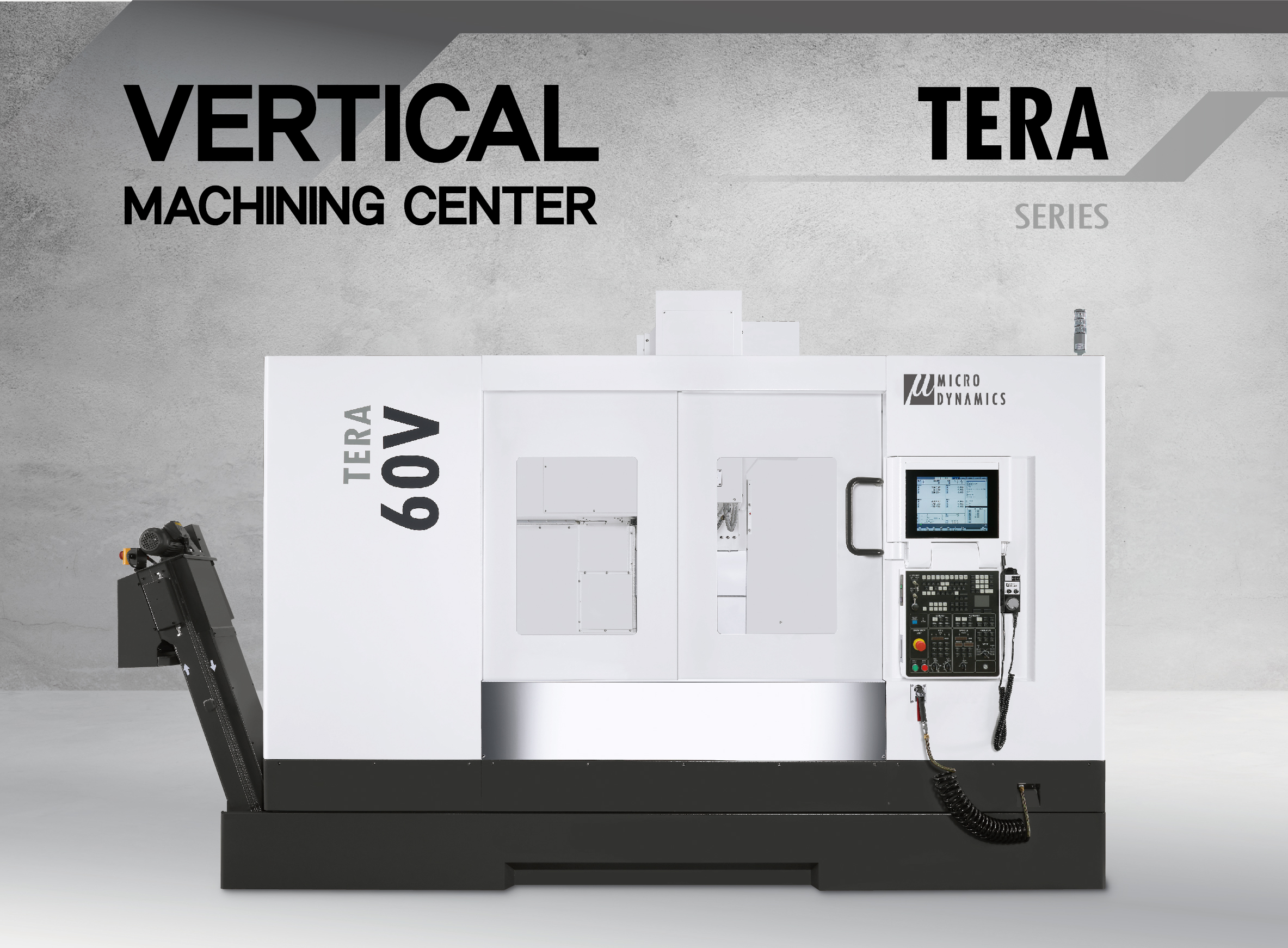

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

QUASER MACHINE TOOLS, INC.

Product Description :

The MV1 series machines have a legendary history of high quality and proven performance, the New MV184 series has an even greater degree of reliability and performance. The design concepts of the new MV184 series combine advanced technology, performance and value for various machining applications.

Quaser produces this machine layout with the state-of-the-art digital design. Taking into consideration easy repair to reduce downtime. The MV184 series is the choice to increase part production.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

FAIR FRIEND ENTERPRISE CO., LTD.

Product Description :

1. Improve tools life and cutting efficiency, especially ideal for particular process requirements of brittle or hard、 high-temperature superalloy and composite materials.

2. Increased precision and quality of the workpiece to achieve excellent cutting results. (smooth edge)

3. Perfected ultrasonic control technology for easy selection, automatic frequency, and power adjustment.

4. The strong chipping of chassis concentrates the chips into the path as ensures high efficiency.

5. Anti-scale cover + KEVLAR armor material, used in glasses, ceramics super hard metal processing which can preventing dust protection system effectively.。

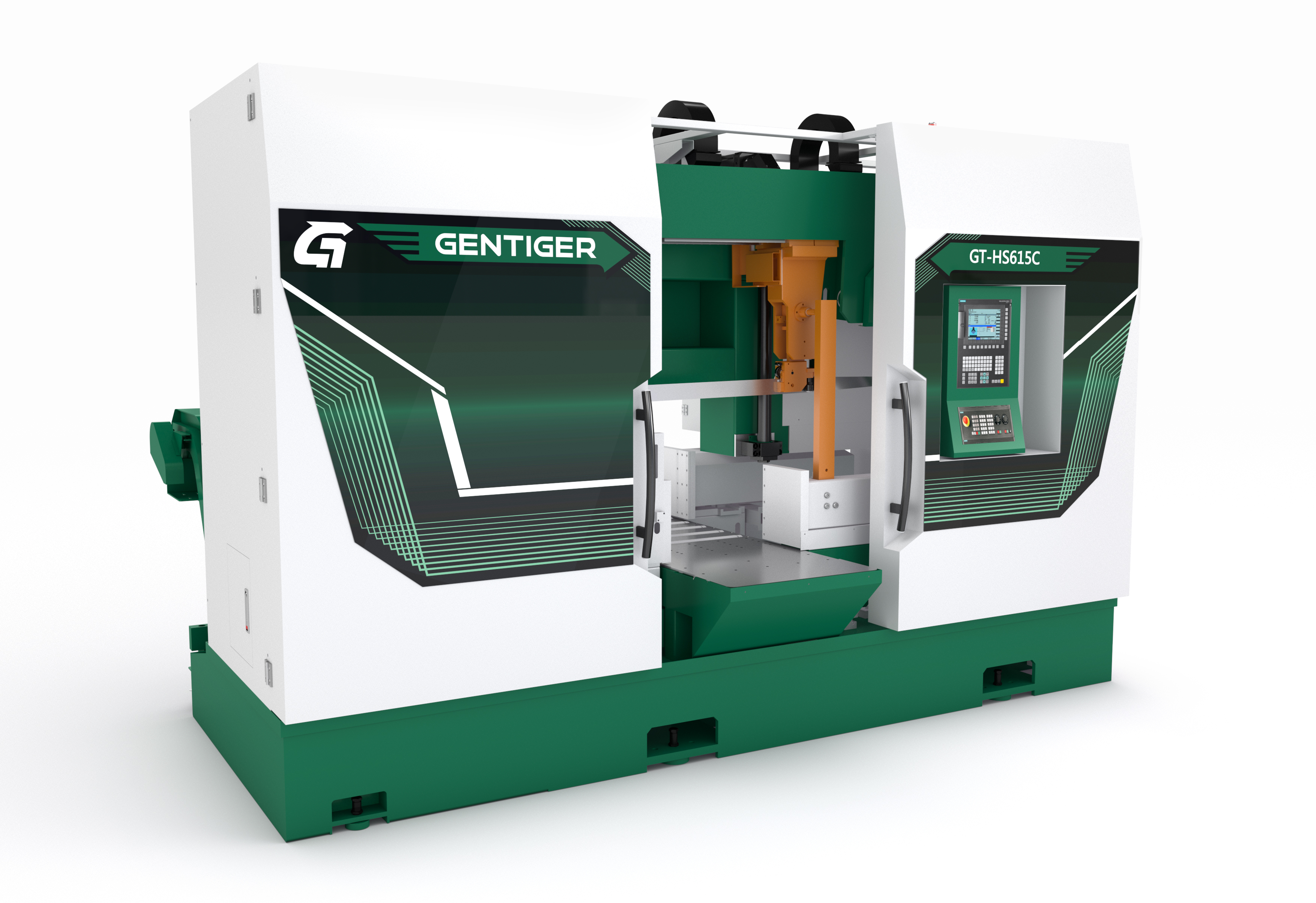

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

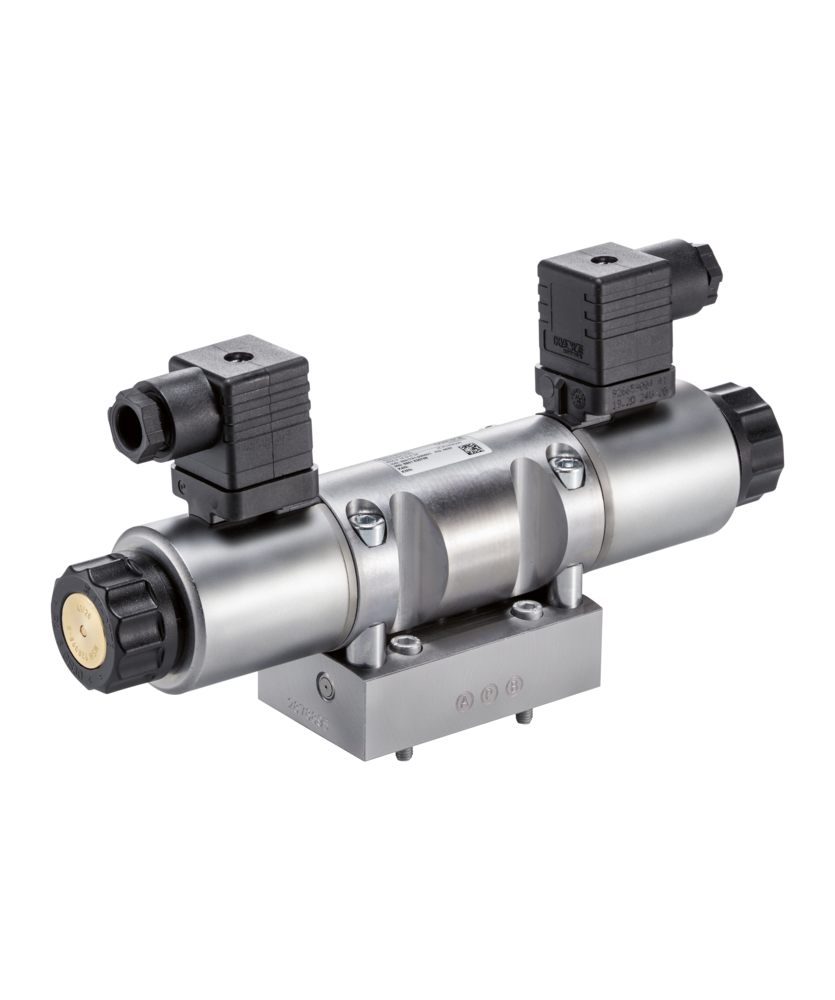

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.