Theme

Digital Transformation

Green Transformation

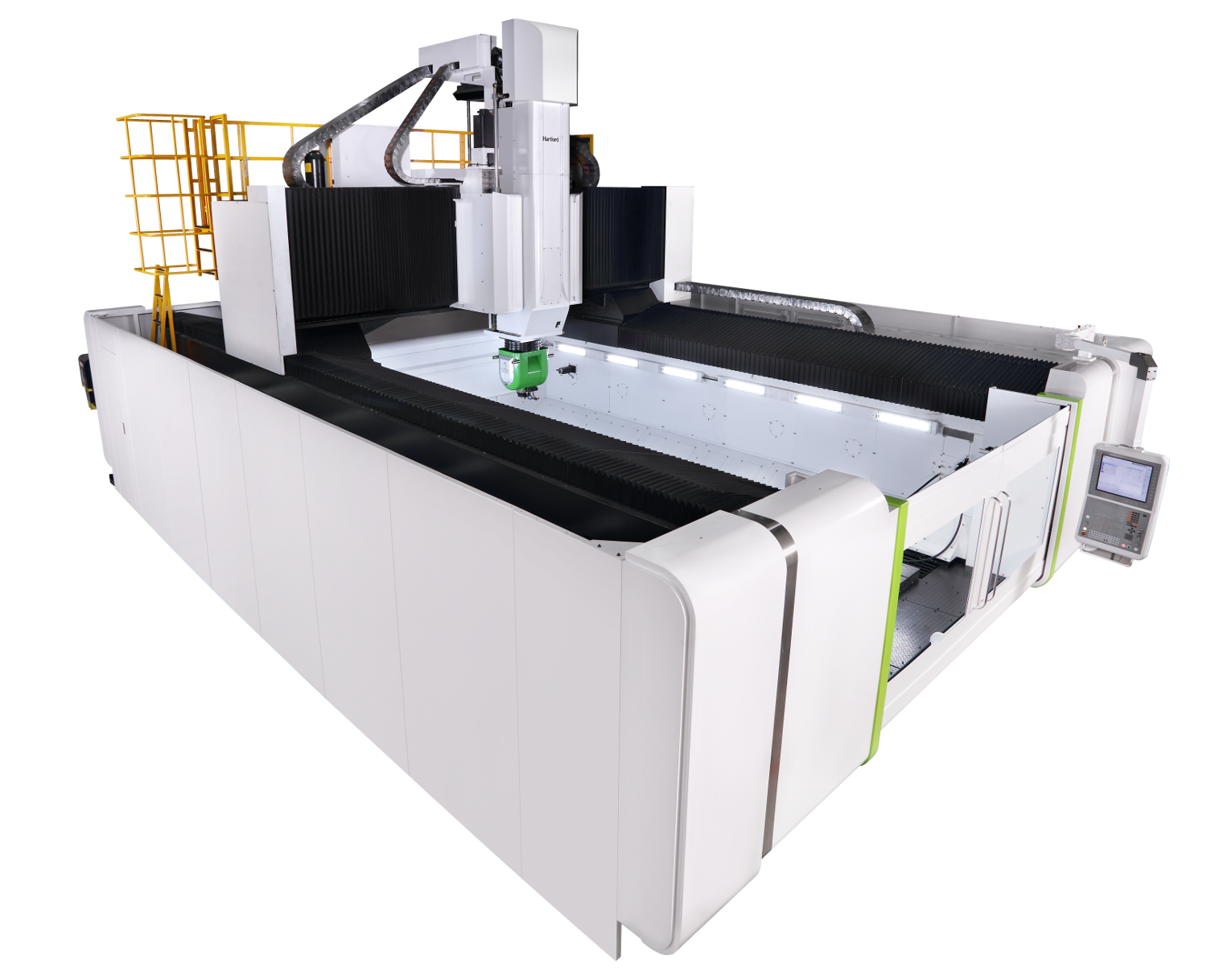

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve

the efficiency of operators.

QUASER MACHINE TOOLS, INC.

Product Description :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

‧HTT-500, the 5-axis horizontal machining center, is Tongtai's new solution of process integration which will definitely meet the demands on high-mix low-volume manufacturing.

‧Excellent machine rigidity and stability to ensure high accuracy during precision machining.

‧Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

‧Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

‧Equipped with APC (auto pallet changer) system to shorten the machine idle time.

‧Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.

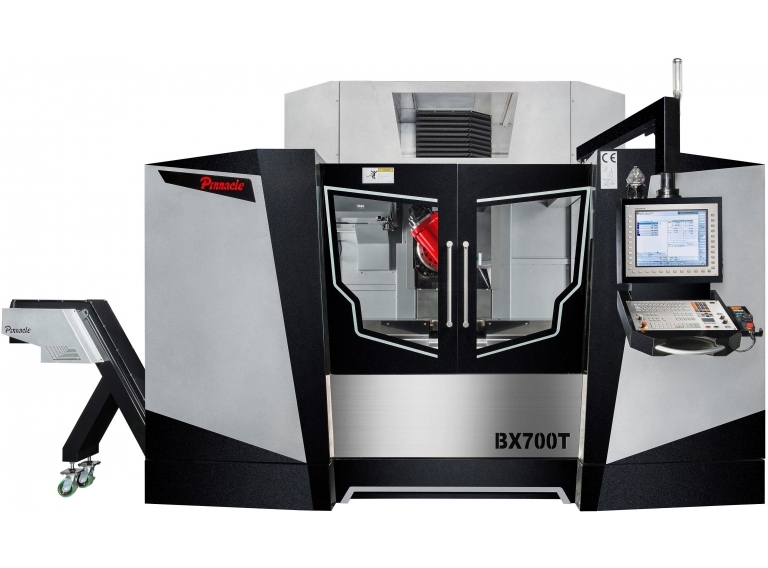

PINNACLE MACHINE TOOL CO., LTD.

Product Description :

2台立式 + 車床? <br />

立式+4軸轉台 + 車床?<br />

5軸機 + 車床?<br />

還在為複雜的工件煩惱買什麼機台嗎? <br />

BX700T絕對是最佳首選! Milling and Turning 銑車複合的五軸加工中心,B軸擺頭+/-120度,搭配內藏式15000轉主軸,內坎式C軸直徑630mm工作台,C軸轉速有800轉及1200轉作選擇。。專利設計,完美結合:最大的加工空間、最小的干涉、高精度及高效率的五軸銑車複合機。一台抵三台,投資成本相對少,佔地空間小。<br />

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

1. T structure bed with high-quality cast-iron frame for enhanced rigidity and stability.

2. Extremely rigid mobile column with linear guide ways ensures stability and cutting accuracy while allowing rapid traverse of the X, Y and Z axes.

3. High rigidity roller type linear guideways, rugged massive linear guideways on X, Y and Z axes maintain precision and ensure a rapid traverse rate.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

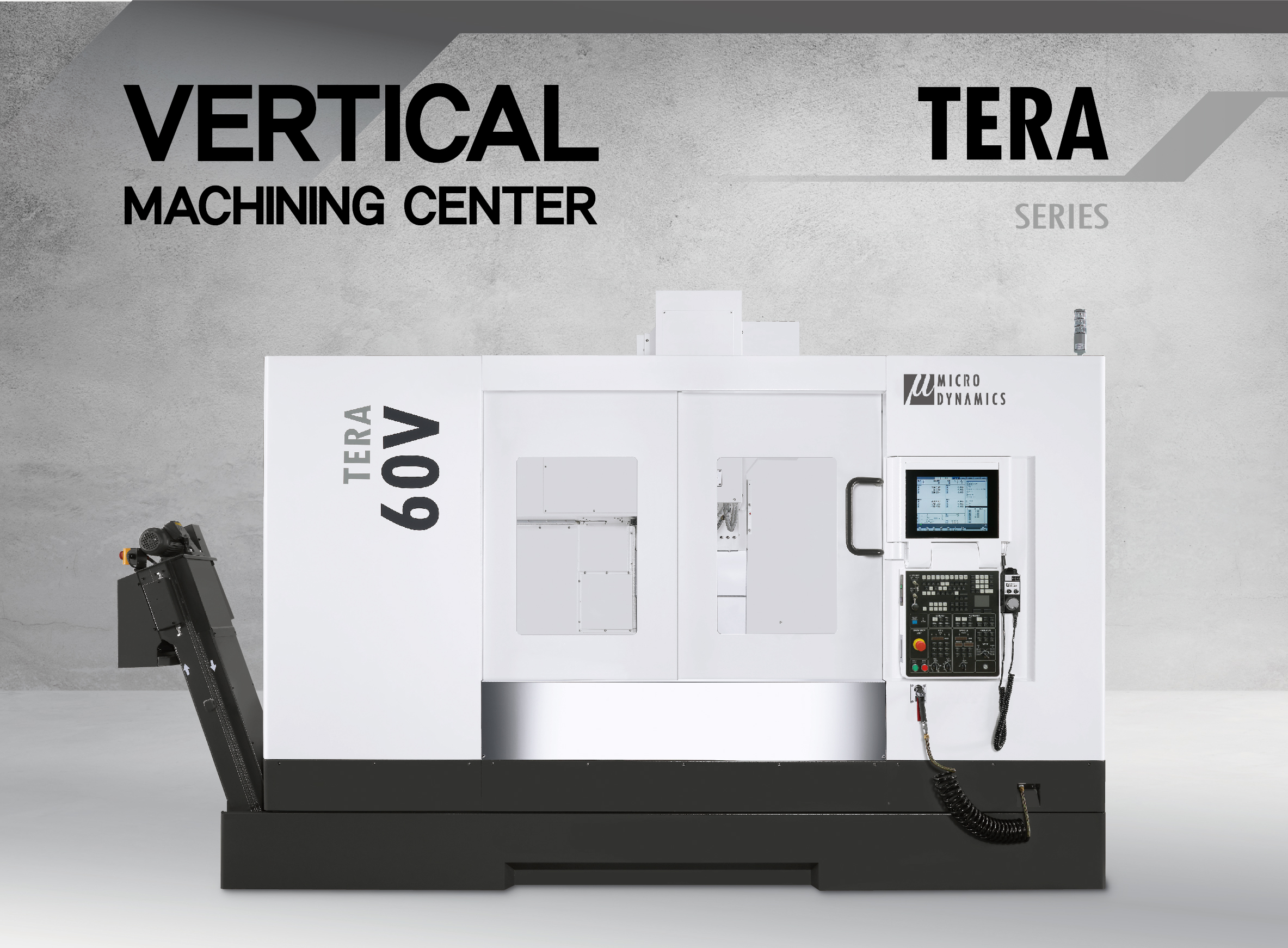

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

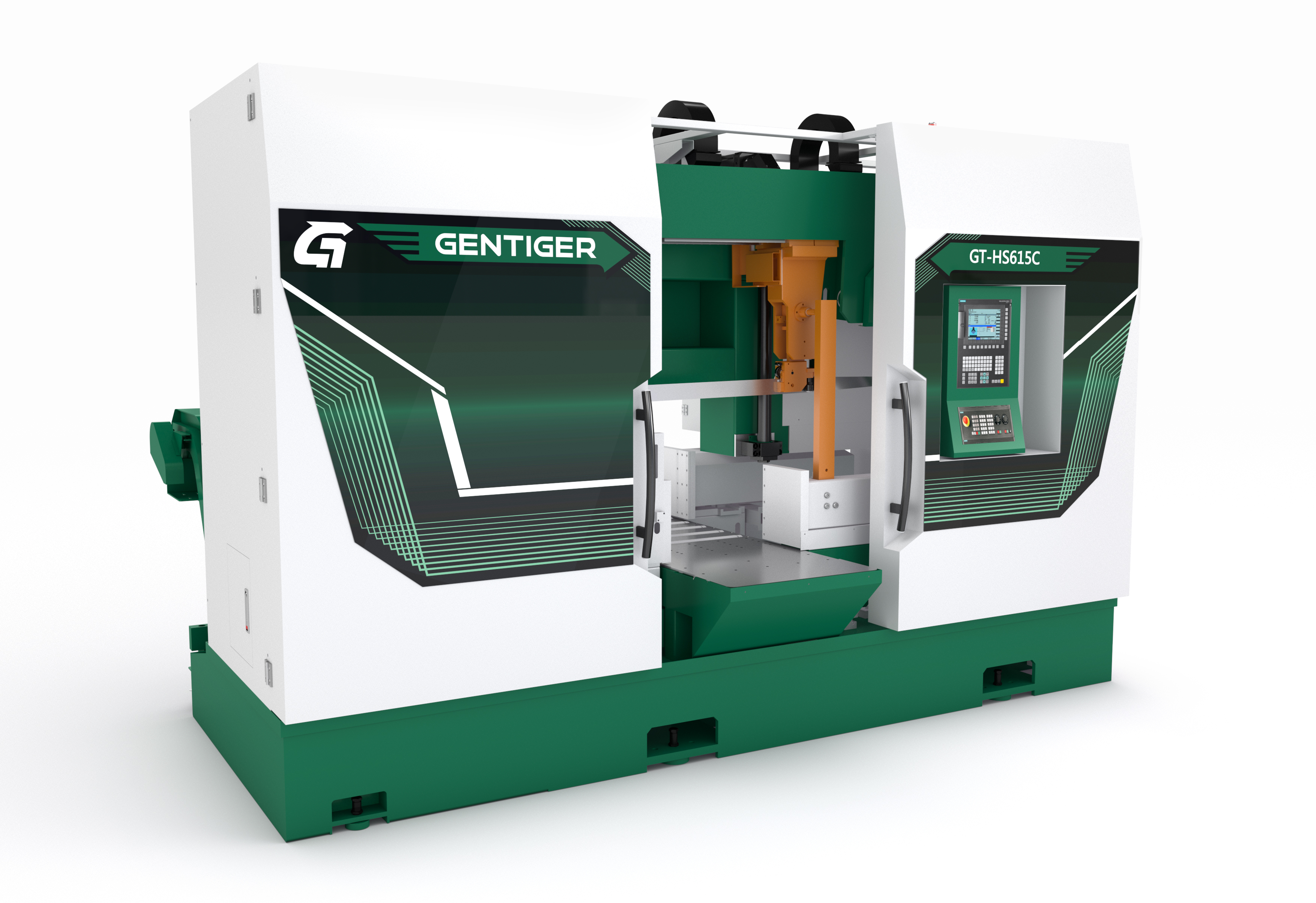

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Product Description :

1. The double column saw frame structure raise rigidity.

2. The main driving wheels are equipped with an encoder for instant feedback and speed compensation.

3. Material sizing and cutting feed by servomotor.

4. The roller bed and dual movable jaw of F&R avoid material drag and squeezing.

5. The arch elevation mechanism uses a laser induction and isn’t limited by the material height and shape.

6. The sawing order can be scanned by QR CODE to establish the parameters and is beneficial for management.

7. Graphical dialogue operation screen, humanized operation, improving operation convenience.

8. Equipped with a multi-function meter that immediately monitors the instantaneous energy consumption and efficiency.

9. High-performance design and stable structure can get the best sawing flatness, reduce material waste and improve efficiency.

10. The machine combines fashion and technology while injecting the meaning of high speed, stability, and eco-friendly.

NUMEN MACHINERY CO., LTD.

Product Description :

* Double column structure and high rigidity design can

provide mold processing industry with high precision

and high efficiency of the performance.

* The superior cutting rigidity, more user-friendly

operation mode and machine stability can improve the

efficiency of operators.