Theme

Digital Transformation

Green Transformation

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

Most Popular High Performance NSV106AS is well suited for superior surface finishing works, specially in automotive, job shop and electronics industries. ■ Large delta machine column and base ensure the highest stability during high speed movement■ High precision roller type guideways on all 3 axes■ High precision linear guideway with 6 slide blocks on X-axis■ High performance YCM in-house designed spindle with low vibration to achieve excellent finish

BUFFALO MACHINERY CO., LTD.

Product Description :

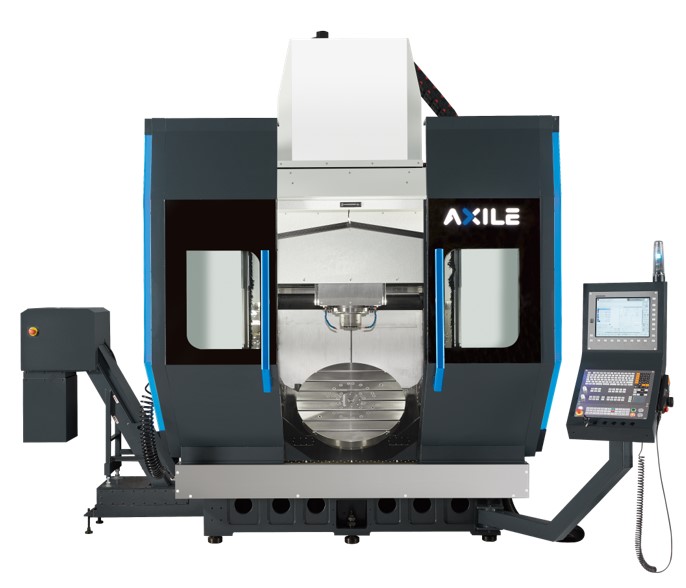

The AXILE G8’s powerful gantry design perfectly balances rigidity and precision, ideal for the machining of complex workpieces.

With a maximum loading capacity up to 1,300 kg on a swiveling, rotary table, complemented by high-performance built-in spindles, the G8's agility enables production of a wide range of large parts and tools.

The G8 MT option offers both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G8 MT can efficiently machine a wider variety of parts, including cylindrical components.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

BUFFALO MACHINERY CO., LTD.

Product Description :

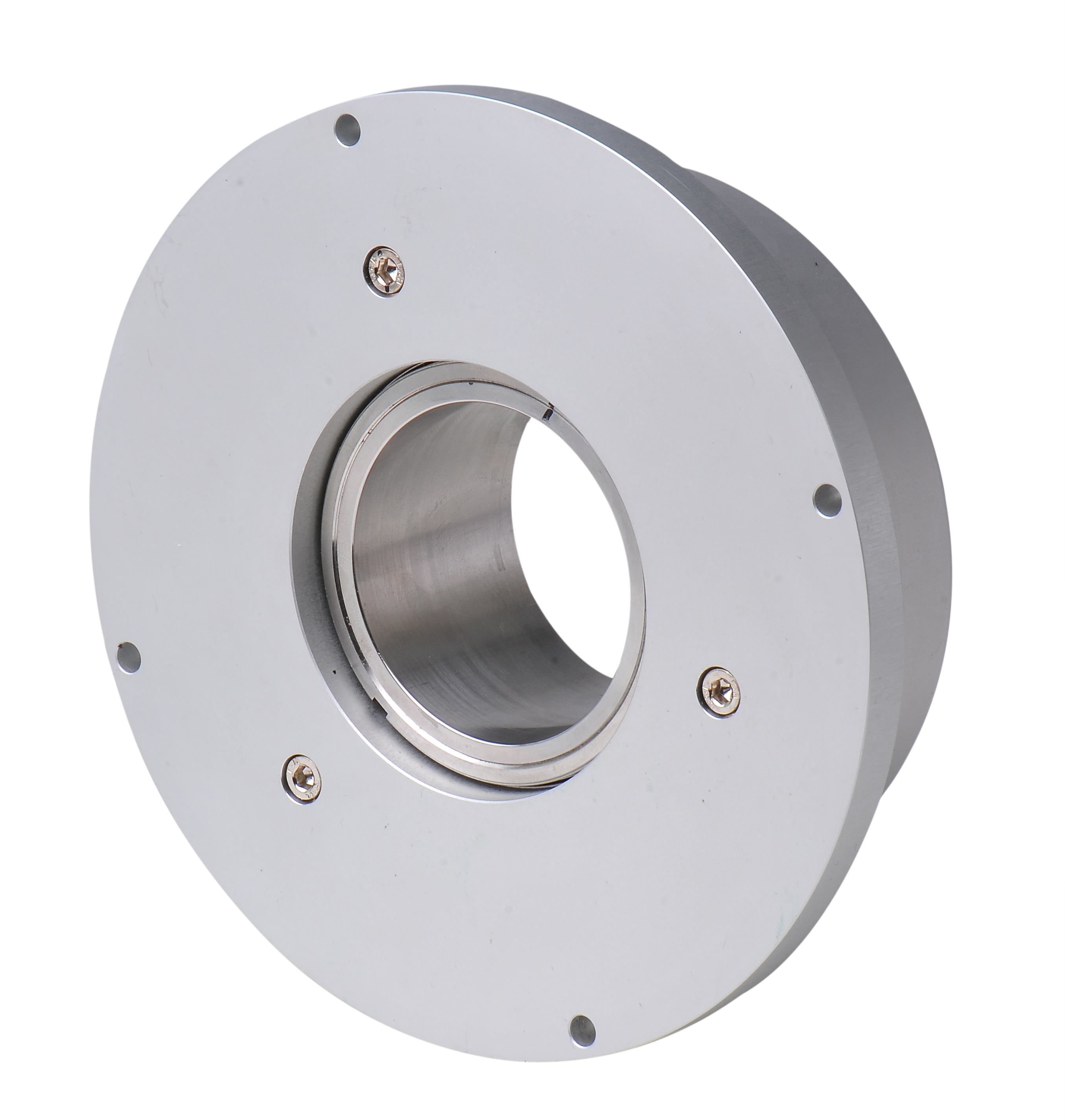

The DC12 is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a maximum table loading weight of 2.5 tonnes and maximum diameter of 2,200 mm X 1,200 mm, the DC12 takes on the larger, heavier parts common in the aerospace, power generation, and die and mold industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the D12 is capable of deep cuts and complex contouring while maintaining utmost precision.

With larger workpieces come more chips, meaning the DC12 features excellent chip removal efficiency, to prolong tool life and ensure no residual interference. Therefore, the DC12 delivers the high surface quality expected by leading manufacturers.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

The 5 axes simultaneous processing, can reduce the times of workpiece unloading and the requirement of the jigs, shorten the processing time and improve performance. C-axis table using the DD motor provides high torque and rigidity and can solve the traditional worm gear backlash and worn problems. High torque and efficiency of the spindle with a complete high-rigidity structure applied results in roughing to finishing can be completed on the same machine, suitable for machining hard materials and non-ferrous materials processing.

X-axis travel: 1300mm

Y-axis travel: 610mm

Z-axis travel: 610/750mm

Table size: 1480x610mm

Max. table load: 1600kg

Spindle speed: 12000rpm

C-axis speed: 800rpm

X/Y/Z-axis rapid traverse: 36/36/30 m/min

Tool storage capacity: 30T

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.