Theme

Digital Transformation

Green Transformation

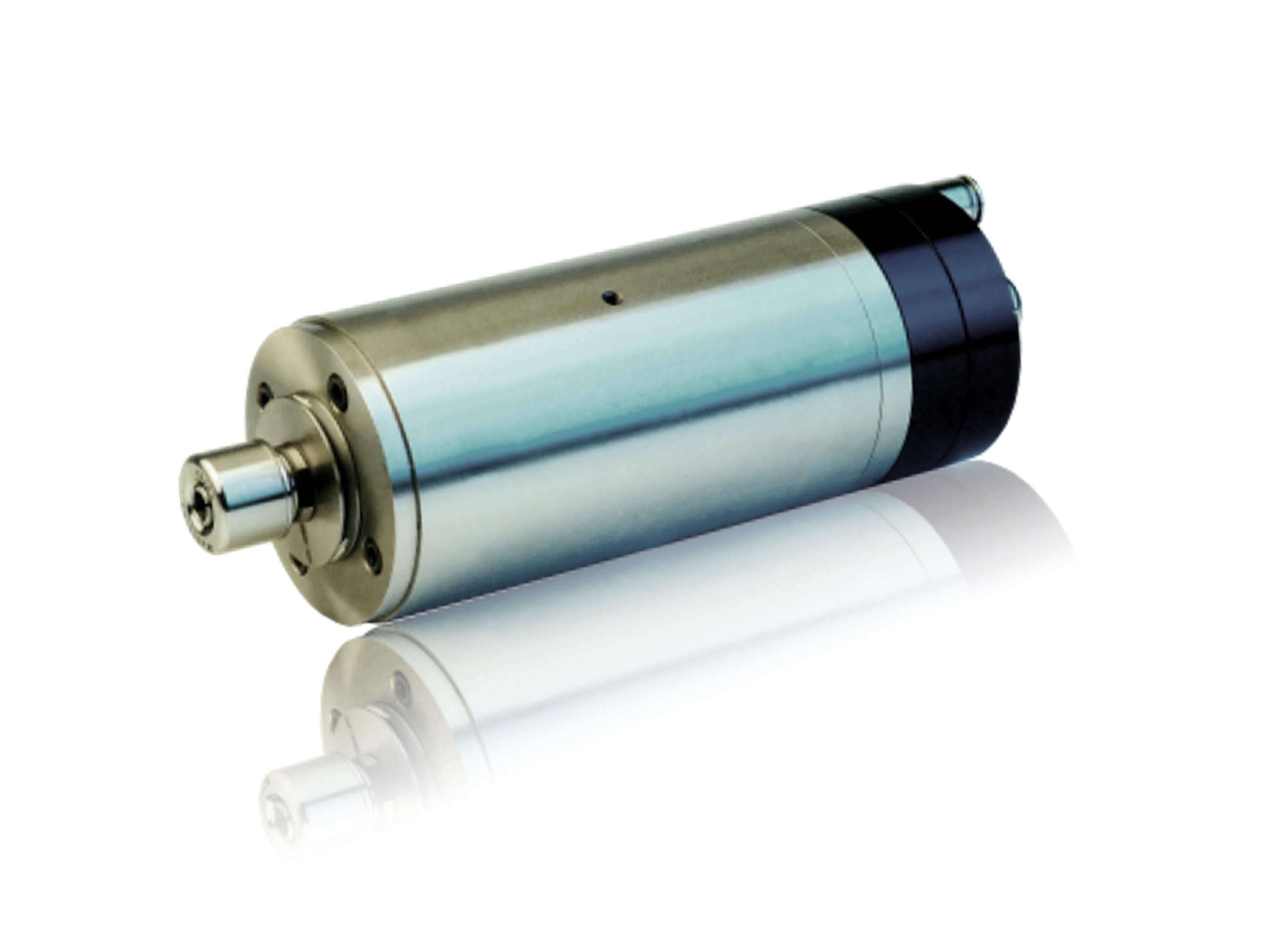

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 45mm

Tool interface : SD6

Maximum speed (rpm) : 50000 RPM

Lubrication : Grease

Motor power : 0.45/0.54 Kw

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The aluminum round jaws(FW-A10050) are suitable for extra bigger outer dia. (thin pipe.).

This type of round jaws can cover the outer dia. of work piece enable to decrease deformation and increase the accuracy.

For example: Type of FW08 can hold parts with outer dia. of 200mm.

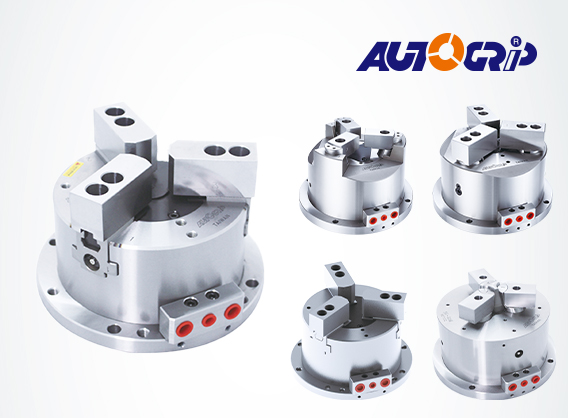

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

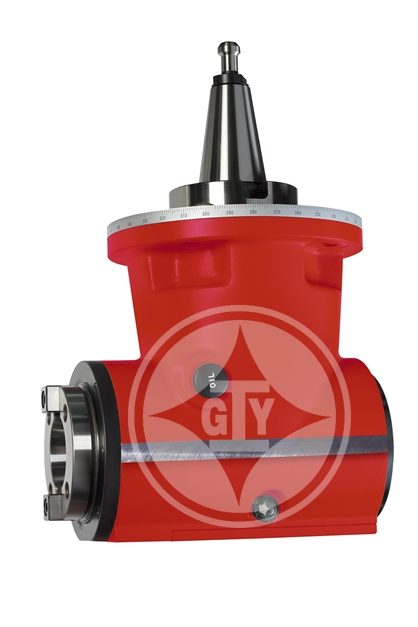

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

ZHENG LUNG INDUSTRY CO., LTD.

Product Description :

精密迴轉頂針- 工廠自行生產製造, 熱處理至HRC60度.<br />

有多種不同功用和負重之全系列頂針可供選擇使用.<br />

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.