Theme

Digital Transformation

Green Transformation

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Pneumatic pressure status.

Support Front/Rear chuck configuration.

Abnormal pressure loss alarm.

Wireless signal transmission.

TAIKI INDUSTRIAL CO., LTD.

Product Description :

The aluminum round jaws(FW-A10050) are suitable for extra bigger outer dia. (thin pipe.).

This type of round jaws can cover the outer dia. of work piece enable to decrease deformation and increase the accuracy.

For example: Type of FW08 can hold parts with outer dia. of 200mm.

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Spindle Taper:ISO-50

◎Outside Diameter of Flange:Ø250 / Ø300

◎Max. Speed:800RPM / 2000RPM

◎Can be opposite-side milling, no need to correct the accuracy again.

◎Spindle water repellent.

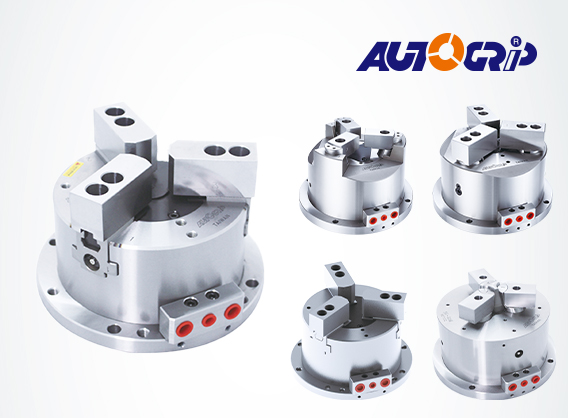

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

GREEN ECO PRO CO. LTD.

Product Description :

Precision filtration system

Due to different grinding and processing materials, the particle size, quality, and hardness of the materials to be filtered will also vary. For this reason, our filtering equipment was designed, which can be used for quartz, silicon carbide, semiconductor grinding, electrical discharge machining, or high precision requirements and can effectively intercept fine impurities.

Continuous/batch processing

Customized tungsten steel stirring motor

Filter material saturation alarm

GREEN ECO PRO CO. LTD.

Product Description :

Oil Mist Collectors

Smart Alert Flagship Series

When the high-speed processing material that produce heat, and then heat to steam out the water, if the coolant tank of waste oil or other oil without correct handle, this time Processing heat will produce oil mist.

With one integrated mechanical design aesthetics

High efficacy with Mini Size

Low Decibel 65 db

Vibration rate G2.5mm/s

Unique development 2D turbine Wheel

Recycle oil above 99%

Intelligent Alert

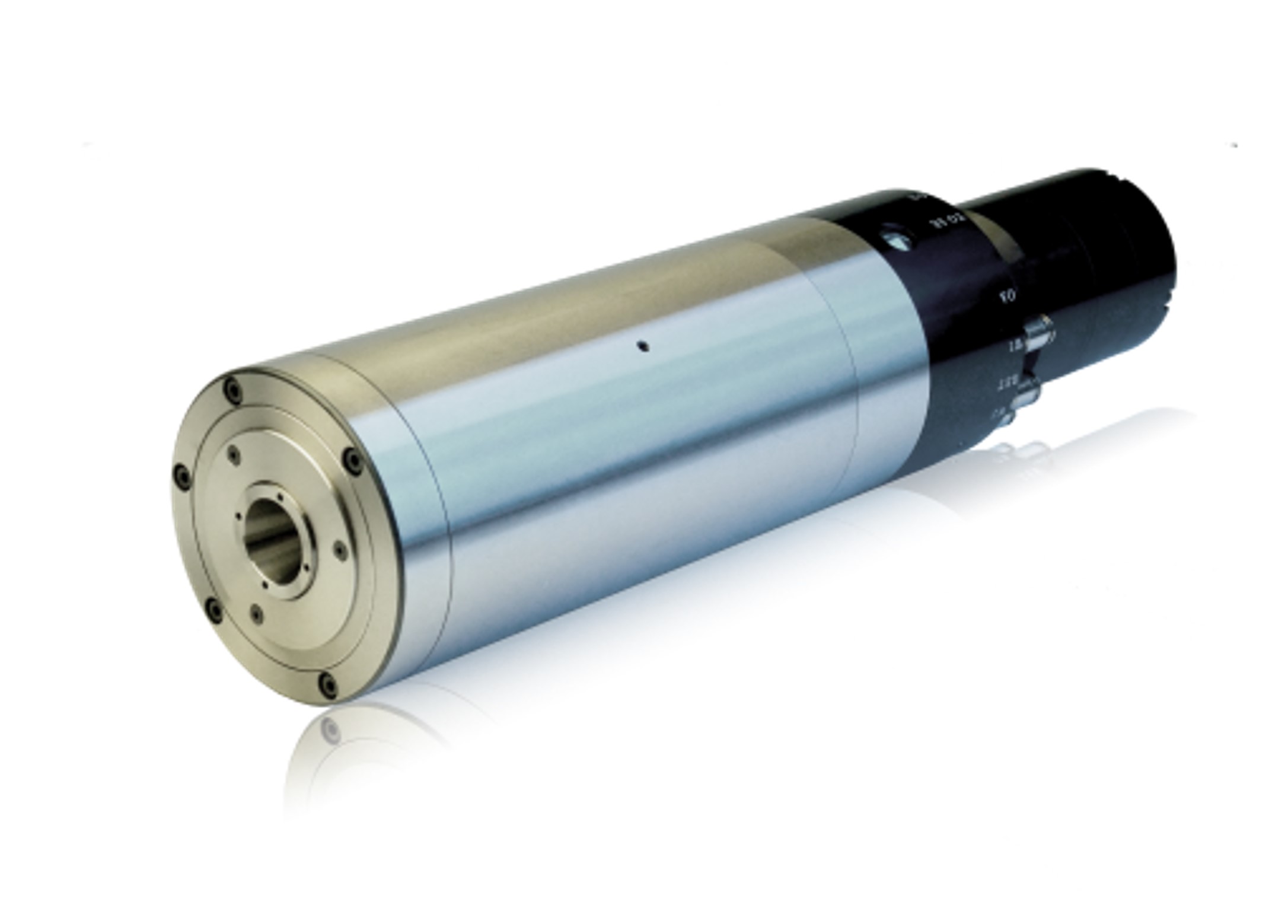

SPINDLEX TECHNOLOGIES CO., LTD.

Product Description :

Spindle housing diameter : 100mm

Tool interface : HSK-E32

Maximum speed (rpm) : 30,000 RPM

Lubrication : Grease

Motor power : 3.5/5.5 Kw

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Spindle Taper:ISO-50

◎Outside Diameter of Flange:Ø250 / Ø300

◎Max. Speed:1500RPM

◎Applicable work:

0~800RPM-heavy cutting;

800~1500RPM-finish milling,drilling,boring.

Otennlux Lighting Technology Co.,Ltd

Product Description :

Otennlux LED intelligent signal lights use IO-Link interface, flexible and versatile, and

diversified applications, providing reliable control solutions for Industry 4.0 intelligent

automation industry. Reduce wiring, increase data availability, remote configuration and

monitoring, simple equipment replacement and advanced diagnosis, improve process

efficiency and increase machine availability.

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.