Theme

Digital Transformation

Green Transformation

A Being Kou Tools Co., Ltd.

Product Description :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Brand new upgrade! Introducing the Grip Force Sensor (GFS-100) with advanced gripping technology. Bluetooth 5.0 ensures exceptional wireless connectivity, making your operations smoother. Convenient Type-C charging interface for easy charging, providing continuous power for your work. The high-performance lithium battery offers extended battery life, eliminating concerns about power shortage during work and allowing you to focus on your tasks. GFS-100 supports both Android and iOS systems, ensuring seamless compatibility for a user-friendly experience. With the flexibility to configure as a 2-claw or 3-claw operation based on your actual needs, it provides greater operational versatility. Upgrade your work experience with GFS-100, showcasing the convenience and efficiency of cutting-edge technology.

AUTOCLAWS PRECISION MACHINERY CO., LTD.

Product Description :

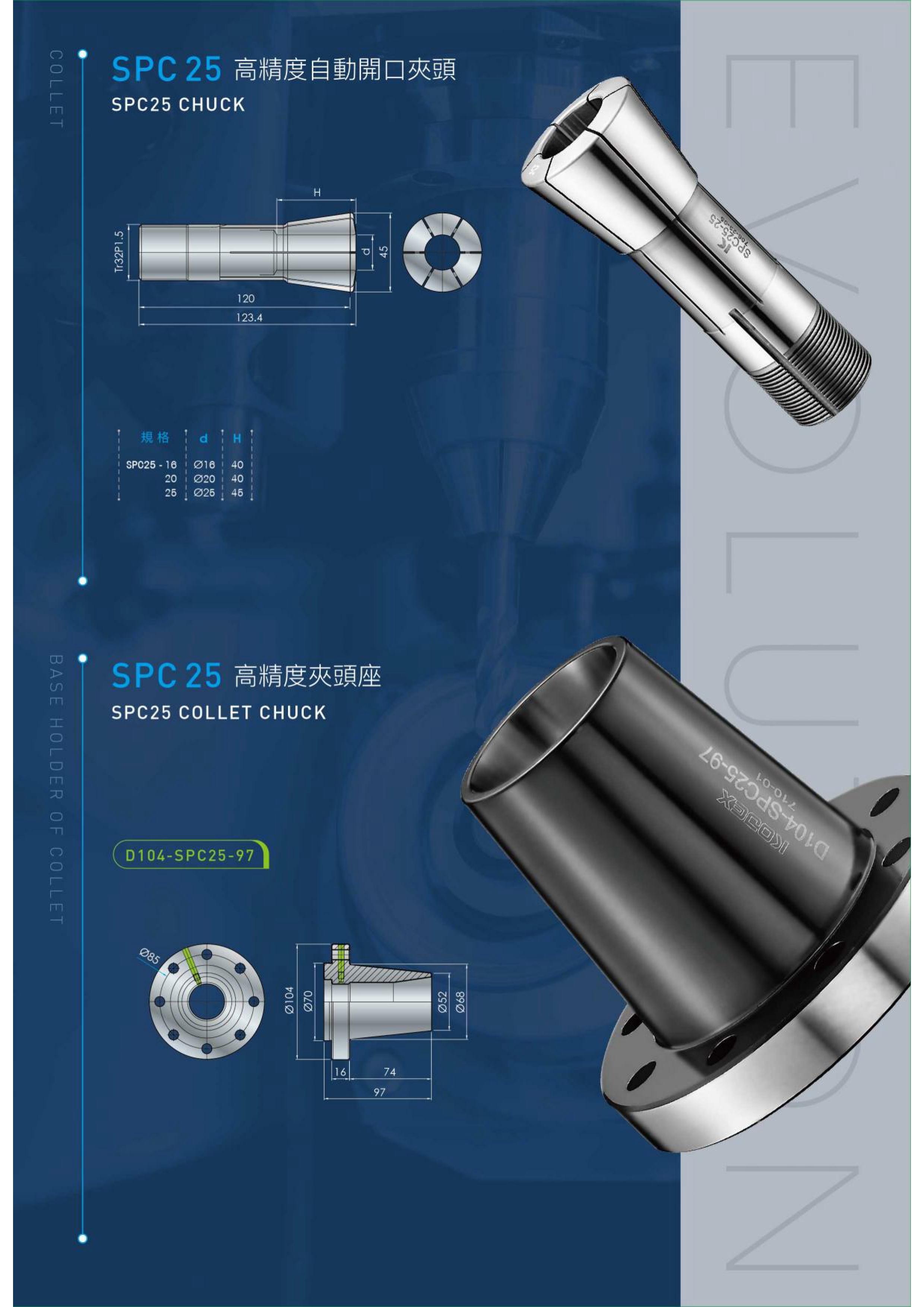

1.Push type collect chuck fixtures can perform high accuracy of axial position locating by the components and mechanical structure design.

2.The collect chuck could be installed onto the lathe machines rapidly and easily without changing the pulling-pipe when it is switched with the exist chuck.

3.Quick-dismantling design: The front cover can be quickly removed

Simply replace the elastic clip can be replaced to immediately turn different sizes or shapes (round, square, hexagonal...) for increased efficiency and versatility.

4.The components through special technology of hardening treatment to archive high intensity,high rigidity and well durability.

5.Professional precision grinding makes it high-precision, precision repeat clamping accuracy.

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

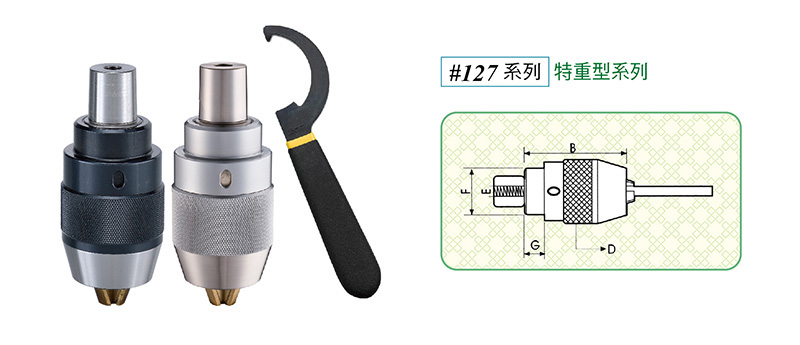

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.